Which PVC alternative makes sense for your specific application? The answer depends entirely on what you’re trying to achieve. As one industry technical guide puts it: “There is no ‘absolutely best’ material, only the ‘most suitable’ one.”

The regulatory landscape is shifting toward stricter controls on traditional PVC formulations. At the same time, alternatives have matured in both performance and cost-competitiveness. Whether you’re responding to compliance requirements or seeking better performance characteristics, the market now offers viable options across nearly every PVC application category.

Why Look for PVC Alternatives?

Regulatory compliance has become the primary driver for PVC alternatives, overtaking general environmental concerns. The EU REACH regulation now restricts four key phthalate plasticizers (DEHP, DBP, BBP, DIBP) to concentrations below 0.1% by weight, effective since July 2020. More recently, lead content in PVC articles faces the same 0.1% restriction as of November 2024.

These aren’t theoretical concerns for B2B procurement. Products failing to meet these thresholds cannot legally enter EU markets. Similar restrictions exist in other regions, with California Proposition 65 and various Asian regulations creating a patchwork of compliance requirements.

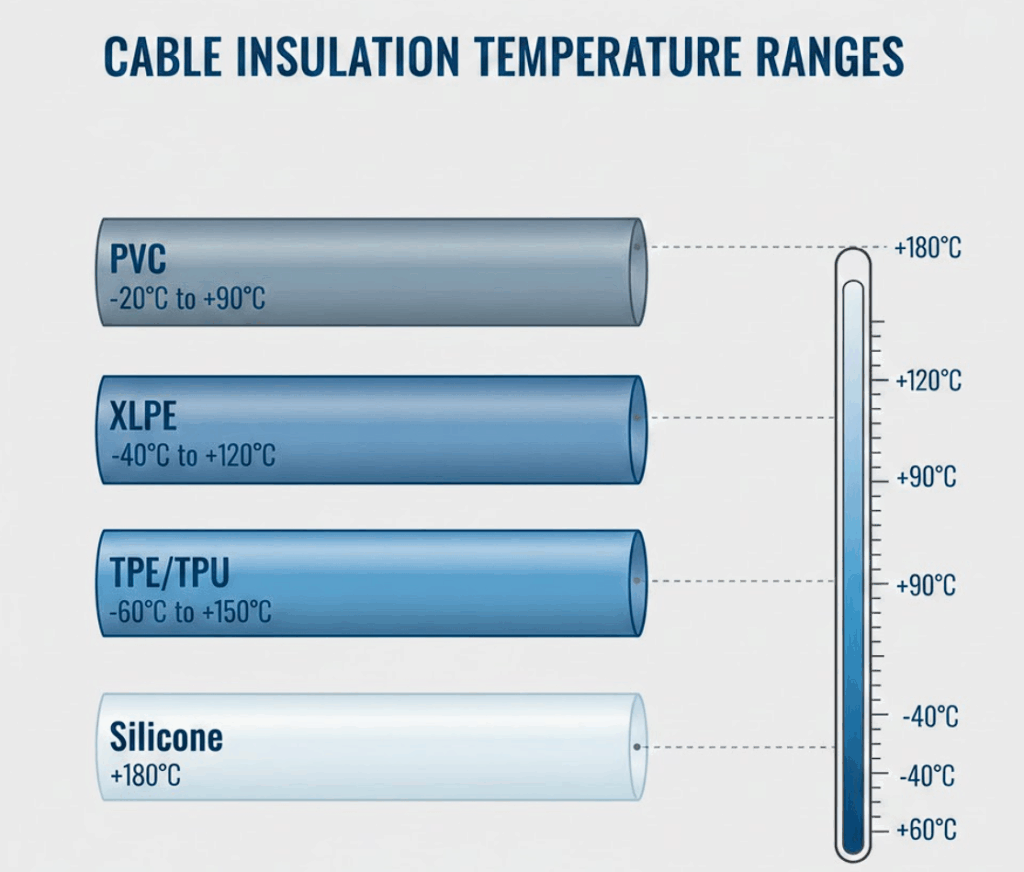

Performance limitations also drive many switching decisions. Standard PVC operates within a -20C to +70C temperature window. Applications requiring higher heat resistance, greater pressure tolerance, or improved chemical resistance often find better solutions in alternative materials.

Polyolefins: HDPE and Polypropylene

High-density polyethylene (HDPE) and polypropylene (PP) represent the most direct PVC substitutes for many applications. Both are petroleum-based thermoplastics that process using similar methods: injection molding, extrusion, and thermoforming.

HDPE for Piping and Containers

HDPE outperforms PVC in several critical piping metrics. According to WL Plastics, HDPE can withstand twice the pressure of comparable PVC pipes. Flow rate tolerance is equally impressive: HDPE maintains structural integrity at rates up to 14 feet per second, versus PVC’s 5.5 fps limit.

Flexibility advantages matter for installation. HDPE has a bend radius of approximately 25 times its outer diameter. PVC requires 200-250 times its outer diameter for the same operation. This difference translates directly to reduced fittings and faster installation in applications with directional changes.

For a detailed comparison of HDPE and PVC piping, including pressure ratings and lifespan considerations, the performance gap becomes even clearer in high-stress applications.

Polypropylene for High-Heat Applications

PP costs approximately $0.27 per kilogram, while PVC costs roughly $0.28 per kilogram. This near-identical pricing eliminates cost as a barrier for polyolefin alternatives in many applications.

The performance advantage appears at elevated temperatures. PP withstands temperatures up to 130C, significantly exceeding PVC’s temperature limits of 70C for standard grades. Food packaging, autoclavable containers, and hot-fill applications benefit from this expanded thermal envelope.

PP also avoids the chlorine chemistry concerns associated with PVC manufacturing. For companies with sustainability targets beyond regulatory minimums, this represents an additional consideration.

Specialty Alternatives by Application

Different applications have developed their own preferred alternatives based on specific performance requirements.

Electrical and Cable Insulation

Cross-linked polyethylene (XLPE) has become the dominant alternative for medium and high-voltage cable insulation. The performance difference is substantial: XLPE has a maximum working temperature of 90C versus PVC’s 70C limit. Under short-circuit conditions, XLPE withstands conductor temperatures up to 250C for one second, compared to 160C for PVC.

For applications requiring extreme temperature tolerance, silicone rubber operates from -60C to +180C. Thermoplastic elastomers (TPE/TPU) offer an intermediate option at -50C to +105C while maintaining flexibility at cryogenic temperatures.

The market trend across these materials is toward higher-performance insulation as power density increases in modern electrical systems.

Packaging Materials

PET (polyethylene terephthalate) offers a compelling combination for packaging applications: it costs approximately 20% less than PVC while providing superior recyclability. Europe’s PET recycling rate reaches 58%, while PVC packaging recycling remains in the 6-10% range depending on region and measurement methodology.

For blister packaging and thermoformed trays, PET provides comparable clarity and barrier properties. The recyclability advantage increasingly matters as extended producer responsibility regulations expand globally.

Medical and Food Contact

Thermoplastic elastomers are experiencing significant growth in medical applications. The global medical-grade TPE compounds market is expanding at a compound annual growth rate of 9.55%, projected to reach $3.41 billion by 2035.

TPE offers advantages for face masks, cushions, and tubing where skin contact occurs. Unlike plasticized PVC, TPE doesn’t require added plasticizers that might migrate into contact with patients or food.

For applications where non-phthalate plasticizers are acceptable, modified PVC formulations can maintain material performance while meeting regulatory requirements.

Modified PVC as a Middle Ground

Complete material substitution isn’t always the most practical path. For existing PVC processing infrastructure, reformulation with compliant plasticizers often makes more business sense than equipment changeover.

DOTP (dioctyl terephthalate) demonstrates 42% lower migration rates compared to traditional DBP. It meets FDA 21 CFR requirements and REACH compliance while maintaining the processing characteristics PVC manufacturers expect. Other non-phthalate options include ATBC (EU 10/2011 compliant), TEC (ISO 10993 certified), and ESO (USDA BioPreferred).

This approach works particularly well when regulatory compliance is the primary driver rather than fundamental performance limitations. The debate between “greening” PVC versus complete replacement often resolves to application-specific economics. Regulations tightening globally make the compliant plasticizer route increasingly attractive for manufacturers with established PVC operations.

The phthalate phase-out is accelerating, but these restrictions apply to specific compounds, not to PVC as a material category. Rigid PVC (uPVC) contains no plasticizers and faces none of these concerns. Flexible PVC requires plasticizers, and the difference between these formulations determines which applications need reformulation.

Making the Selection Decision

Material selection should follow application requirements, not material preferences. A German housing renovation study quantified this principle: replacing PVC with alternative materials increased costs by approximately 2,250 euros per average-sized apartment when no technical benefit justified the substitution.

Start with three questions:

- What performance parameters matter? Temperature range, pressure rating, chemical exposure, and flexibility requirements narrow the field quickly.

- What regulatory requirements apply? EU REACH, FDA food contact, medical device standards, and regional regulations each define acceptable material options.

- What’s the total cost picture? Material cost, processing changes, equipment compatibility, and qualification testing all factor into realistic comparisons.

PVC alternatives now exist across every major application category, with competitive cost and performance in many cases. HDPE and PP offer direct substitution for piping and containers at near-identical pricing. XLPE dominates electrical applications above PVC’s thermal limits. PET provides cost and recyclability advantages for packaging. For applications where PVC’s processing advantages matter, reformulation with compliant plasticizers addresses regulatory concerns without material changeover.

The selection decision rests on application requirements. Start there, not with material ideology, and the appropriate alternative becomes clear.