PVC artificial leather, also known as polyvinyl chloride (PVC) synthetic leather, is produced by mixing PVC resin with additives such as plasticizers, stabilizers, fillers, and pigments. These components are then processed through coating, embossing, and printing techniques. PVC artificial leather is valued for its soft texture, wear resistance, ease of cleaning, and resistance to deformation. It can mimic the texture and appearance of natural leather, making it an ideal substitute. Despite its lower breathability and moisture permeability compared to natural leather, PVC artificial leather offers sufficient strength and wear resistance, along with advantages such as simple production processes, abundant raw materials, uniform quality, lightweight, water resistance, and low cost. These characteristics make it widely used in clothing, footwear, bags, furniture, decorations, and various industrial accessories. With advancements in plastic varieties and processing technologies, a variety of PVC artificial leather products have been developed.

High Wear-Resistant PVC Artificial Leather: Raw Material Selection and Proportioning

Key components include PVC resin, plasticizer DINP/plasticizer DOTP/Plasticizer DOP, stabilizers, fillers, and pigments. PVC resin serves as the primary material, directly influencing the quality and performance of the final product. Plasticizers enhance flexibility and extensibility, while stabilizers prevent thermal decomposition and photoaging during processing and use. Fillers and pigments affect both the aesthetic and physical properties of the material.

High-wear-resistant PVC artificial leather typically consists of a surface treatment layer, a face layer, a foamed layer, an adhesive layer, and a substrate. The face layer, composed of plasticizers, PVC powder, stabilizers, antioxidants, ultraviolet absorbers, and fillers. Experimental results show that optimizing the face layer formulation can significantly improve wear resistance. For instance, a formulation with 45–100 parts of plasticizer, 75–100 parts of PVC powder, 1–10 parts of stabilizer, 0.1–0.9 parts of antioxidant, 0–0.8 parts of ultraviolet absorber, and 0–30 parts of filler achieved a wear resistance of 9.8 N·20,000 cycles, surpassing the standard rating of 4.

Figure 1 illustrates the cross-sectional structure of high-wear-resistant PVC artificial leather, which typically consists of a surface treatment layer, face layer, foamed layer, adhesive layer, and substrate.

Production Process Flow

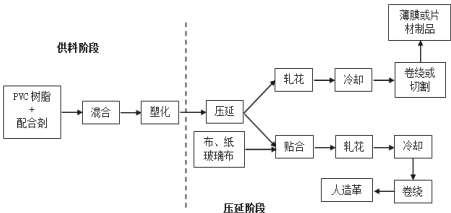

The production process of high-wear-resistant PVC artificial leather involves several key steps: batching, stirring, filtering, extrusion, calendaring, cooling, and cutting. Precise control of temperature, pressure, and rotational speed during these processes is essential to ensure the structural integrity and performance of the final product. To enhance wear resistance, some manufacturers incorporate wear-resistant additives during specific stages of production to modify the PVC resin.

Common production methods include calendaring, coating, and extrusion. The calendaring method involves mixing PVC resin, plasticizers, and fillers, followed by calendaring to form sheets, embossing, and drying.

Figure 2 outlines the production process using the calendaring method. Key steps include batching, mixing, filtering, extrusion, calendaring, cooling, and cutting. This method ensures uniformity, high strength, and excellent wear resistance by precisely controlling temperature, pressure, and rotational speed during processing.