“Plasticizers in wire can migrate out of terminated ends and essentially attack the resin used in contactor bodies over the course of about 5 years… weakening them, which led to cracking and separation of power terminal mounting devices.” This practitioner account from an electrical forum captures a reality I encounter frequently: plasticizer selection failures that manifest years after installation.

Temperature rating matters, but compatibility and migration behavior determine whether your cable survives its service life. The molecular structure of your plasticizer choice explains why some formulations last decades while others fail within years.

Key Performance Factors for Cable Plasticizers

Four properties drive plasticizer selection for wire and cable: temperature rating, volatility, electrical properties, and migration tendency. Most selection guides focus exclusively on the first two. That approach misses half the picture.

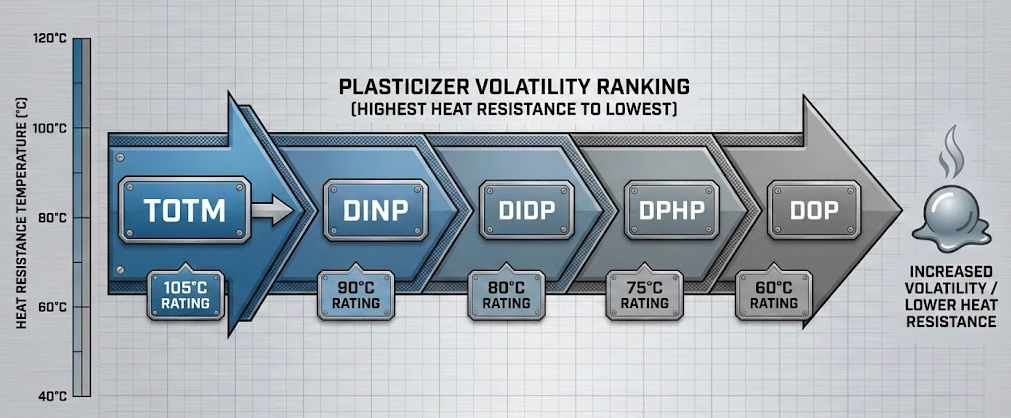

Temperature determines your baseline choice. For 60C-rated cables, standard phthalates like DOP work adequately. At 70C, DIDP or DINP provide better stability. For 90C applications, move to DTDP or DIDP blends. High-temperature 105C cables require trimellitates like TOTM.

Volatility correlates directly with heat resistance. The ranking from highest to lowest heat resistance: TOTM > DTDP > DUP > DIDP > DINP > DOTP > DOP. This hierarchy explains why DOP-plasticized cables lose 30% of their plasticizer content after just 30 hours at 100C. That volatility loss causes brittleness and electrical failures.

Migration matters as much as temperature. I’ve reviewed failure analyses where cables operated well within their temperature ratings yet degraded from plasticizer migration into adjacent materials. The nuclear industry documented this phenomenon: PVC signal cables cracked after 30 years at only 25C. Migration occurs regardless of temperature rating – it just happens faster at elevated temperatures.

Plasticizer Comparison for Wire and Cable Applications

Phthalate Plasticizers

DOP (di-2-ethylhexyl phthalate) remains the benchmark for general-purpose cables despite regulatory pressure. It offers good plasticizing efficiency – 30 phr achieves Shore A 70 hardness. The molecular structure provides excellent compatibility with PVC.

DINP and DIDP offer improved heat stability over DOP. DIDP shows 76% less evaporation than DOP, making it suitable for appliance cords and automotive wire up to 90C. Both phthalates face increasing regulatory scrutiny in consumer applications.

Non-Phthalate Alternatives

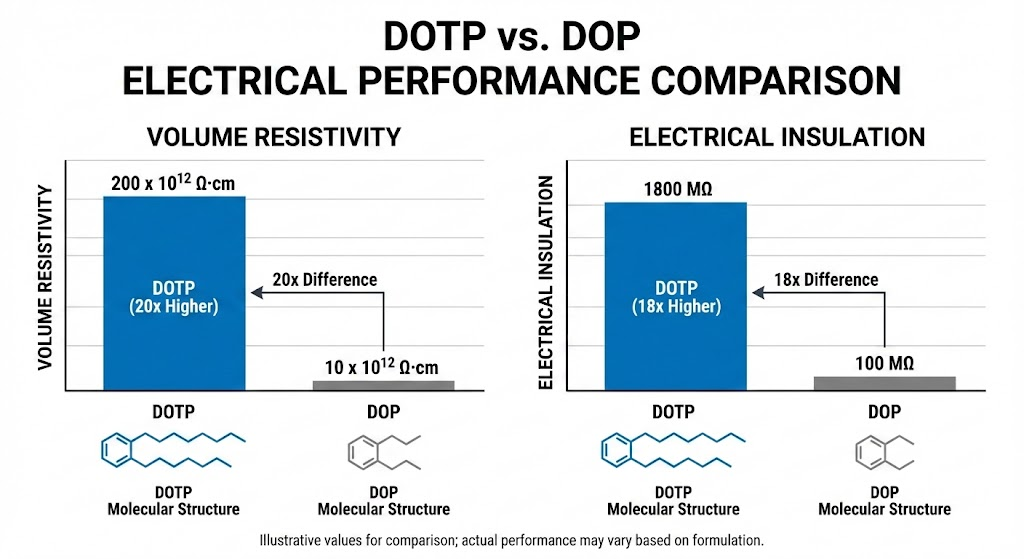

DOTP (dioctyl terephthalate) is not simply a regulatory-driven DOP replacement. The electrical properties are genuinely superior: volume resistivity 20 times greater than DOP, and electrical insulation performance 18 times better. These advantages matter for high-frequency or high-voltage applications.

The trade-off? DOTP requires formulation adjustments. The molecular structure differs from phthalates, affecting PVC compatibility and processing behavior. Treating it as a drop-in replacement leads to problems. Per REACH regulations, DOTP provides a compliant alternative without the 0.1% concentration limits that restrict DEHP, DBP, BBP, and DIBP.

DOA (dioctyl adipate) excels in low-temperature applications. Its dielectric constant of 4.13 at 25C/10kHz falls between rigid PVC (~4.0) and DOP (5.16), offering a good balance for electrical insulation. Use it as a secondary plasticizer at 10-30% of total loading for cold-weather flexibility.

High-Performance Options

TOTM (trioctyl trimellitate) delivers unmatched 105C performance with the lowest migration rates. The cost is substantial – approximately three times DINP pricing – and efficiency is lower. Achieving Shore A 70 requires 45 phr versus 30 phr for DOP, compounding the cost impact.

Match TOTM to actual requirements. Many engineers over-specify high-temperature plasticizers when 70C-rated alternatives would perform identically in their application at much lower cost.

Polymeric plasticizers provide the ultimate migration resistance for critical applications. Their high molecular weight virtually eliminates migration but creates processing challenges. Consider them when adjacent materials are sensitive to plasticizer attack.

| Plasticizer | Temp Rating | Dielectric Constant (25C/10kHz) | Relative Cost | Best For |

|---|---|---|---|---|

| DOP | 60C | 5.16 | 1x | General purpose |

| DINP | 90C | – | 1.1x | Automotive, appliance |

| DIDP | 90C | 4.46 | 1.2x | High-temp with flexibility |

| DOTP | 70C | 4.5 | 1.3x | Non-phthalate compliance |

| DOA | 60C | 4.13 | 1.1x | Low-temp secondary |

| TOTM | 105C | – | 3x | High-temp, low migration |

Migration and Long-Term Reliability

Plasticizer migration deserves more attention than it typically receives. The contactor failure described in the introduction – where migrated plasticizer attacked phenolic resin over five years – represents a common pattern. Once migration damage occurs, no effective cleaning method exists. The same solvents that remove plasticizer residue attack the remaining wire insulation.

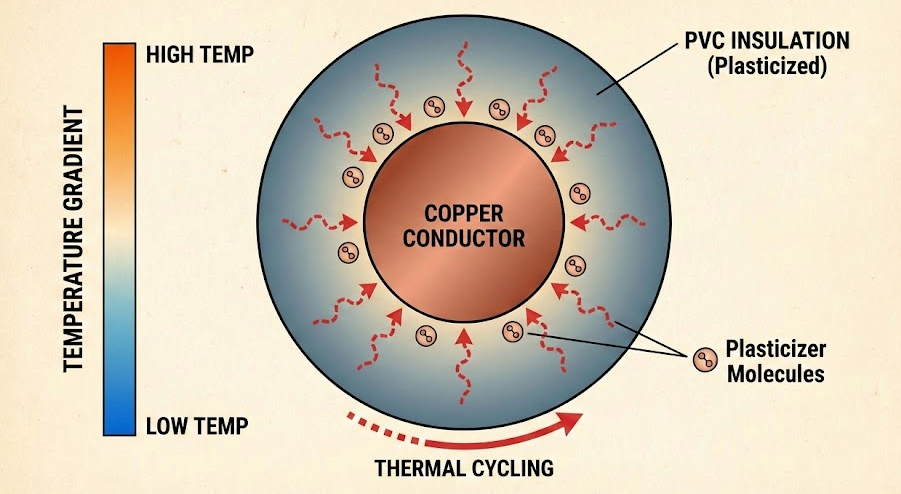

The mechanism follows diffusion kinetics. Academic research on nuclear plant cables measured an activation energy of 89 kJ/mol for DEHP transport, confirming that migration is thermally activated but occurs at all temperatures. Thermal cycling accelerates the process by repeatedly drawing plasticizer toward conductor surfaces.

Historical evidence reinforces this concern. The “green goo” phenomenon in 1960s-70s cables occurred when thermal cycling drew plasticizer to conductor surfaces, dissolving copper traces and creating conductive residue. Modern formulations are better, but the underlying chemistry remains unchanged – plasticizers are not chemically bonded to the PVC matrix.

Migration minimization strategies:

- Select low-volatility plasticizers (trimellitates, polymeric types)

- Avoid adjacent materials sensitive to plasticizer attack

- Consider polyester plasticizer blends for critical applications

- Specify migration testing per ASTM D2199 for qualification

Regulatory Compliance for Cable Applications

Regulatory requirements increasingly influence plasticizer selection, though wire and cable enjoy some exemptions.

REACH Annex XVII restricts DEHP, DBP, BBP, and DIBP to 0.1% concentration limits. However, articles exclusively for industrial use or open-air applications where plasticized material does not contact human skin may qualify for exemption. Wire and cable for industrial settings often falls under this exemption, but verify with your regulatory team for specific applications.

RoHS Directive added the same four phthalates to restricted substances effective July 2019 (most equipment) and July 2021 (medical/monitoring). Electronics within RoHS scope face these restrictions regardless of REACH exemptions.

UL certification requires passing specific tests depending on application:

- UL 83 for building wire: VW-1 flame test, cold bend (0C/-10C), heat shock (150-200C), dielectric withstand (2500V+)

- UL 758 for appliance wiring: minimum 60C/30V rating, bend testing, chemical resistance

Understanding these requirements before plasticizer selection prevents costly reformulation after testing failures.

Practical Selection Framework

Start with temperature requirements, but don’t stop there. The compatibility between plasticizer and adjacent materials determines whether your cable survives its intended service life.

Building wire (70C): DOTP offers the best balance of compliance, electrical properties, and cost. For non-phthalate requirements with better electrical performance, DOTP’s 20x volume resistivity advantage over DOP provides genuine technical benefits beyond regulatory compliance.

Automotive/appliance (90C): DIDP with DOA secondary plasticizer (10-20% of total loading) balances heat stability with cold flexibility. Verify migration compatibility with connector materials.

Outdoor/low-temp: DOA or DOS as secondary plasticizers (up to 30% loading) combined with DIDP primary for freeze-thaw cycling resistance.

High-temperature (105C): TOTM is necessary but expensive. Confirm actual operating temperatures before specifying – many applications labeled “high-temp” operate well below 105C and can use lower-cost alternatives.

The most common selection error I encounter: matching plasticizer only to temperature rating while ignoring migration compatibility with terminal blocks, connectors, and adjacent components. Five years of migration damage costs far more than the upfront savings from cheaper plasticizers.