Plasticizer migration is one of the biggest headaches in the plastics industry – it’s when those chemicals that make plastic flexible slowly leak out over time. This process can make your car dashboard sticky, cause that “new car smell,” or even contaminate food from plastic packaging.

Chemical Strategies to Minimize Plasticizer Migration

High Molecular Weight (HMW) and Polymeric Plasticizers

Large plasticizer molecules are simply too big to escape from plastic easily.

Traditional plasticizers like DEHP have molecular weights around 390 g/mol. Modern HMW plasticizers can exceed 1,000 g/mol, making them 3-4 times heavier.

These bulkier molecules get tangled up in the polymer chains like spaghetti. They can’t wiggle their way to the surface as easily as smaller molecules can. Plus, they’re less likely to evaporate even if they do reach the surface.

Polymeric plasticizers take this concept even further. They’re actually long chains themselves, sometimes containing 10-20 repeating units. This makes migration nearly impossible.

Bio-Based Plasticizers

Plant-based plasticizers offer a double win: they migrate less and they’re safer if they do escape. These molecules, derived from vegetable oils or citric acid, have unique chemical structures that grip polymer chains better.

Epoxidized soybean oil (ESO) is the superstar here. Its multiple binding sites act like Velcro, creating several attachment points with the plastic instead of just one. This multi-point anchoring dramatically reduces how much can leak out.

Citrate-based plasticizers work similarly. They have branched structures that get physically trapped in the polymer network, like a tree branch stuck in a fence.

Internal Plasticization

Internal plasticization is the ultimate solution – you chemically bond flexible groups directly to the polymer backbone. It’s permanent flexibility without any risk of migration because there’s nothing separate to migrate.

Here’s how it works: During polymer production, you add flexible chemical groups as part of the main chain. Instead of mixing in separate plasticizer molecules later, the flexibility is built right into the plastic’s DNA.

The downside? It’s more expensive and requires changing the entire production process. But for critical applications like medical devices or food packaging, it’s often worth the investment.

Mitigation Through Polymer Matrix Engineering

Cross-linking the Polymer Network

Cross-linking creates a 3D mesh that traps plasticizers like fish in a net. You’re essentially creating chemical bridges between polymer chains, turning loose strands into a interconnected web.

The process involves adding cross-linking agents during production or using radiation after the plastic is formed. UV light, electron beams, or chemical catalysts can all trigger this reaction.

Each cross-link reduces the free space plasticizers need to move. Studies show that just 5% cross-linking can reduce migration by up to 70%. The plastic stays flexible because the plasticizers are still there – they just can’t escape.

The key is finding the sweet spot. Too much cross-linking makes the plastic rigid and brittle. Too little won’t stop migration effectively.

Incorporation of Nanoscale Fillers

Adding tiny particles to plastic creates a maze that plasticizers must navigate to escape. Nanoclays, carbon nanotubes, and silica nanoparticles all work as roadblocks.

Clay nanoplatelets are especially effective. These flat, plate-like particles stack up like playing cards throughout the plastic. Plasticizers can’t pass through them and must go around, dramatically extending their migration path.

The bonus? These fillers often improve other properties too. They can make the plastic stronger, more heat-resistant, or better at blocking gases.

Mitigation Through Surface Modification and Barrier Layers

Impermeable Coatings

Applying a barrier coating is like putting plastic wrap over a bowl – it seals in what you want to keep. These ultra-thin layers, often just micrometers thick, block plasticizers from reaching the surface.

Silicon oxide (SiOx) coatings are the gold standard. They’re completely impermeable to most plasticizers and invisible to the naked eye. The coating process uses vacuum deposition, where silicon compounds are vaporized and condensed onto the plastic surface.

Aluminum oxide layers work similarly but offer even better barrier properties. They’re often used in food packaging where zero migration is critical.

Multi-layer coatings provide the best protection. You might have a tie layer for adhesion, a barrier layer for blocking migration, and a protective top layer for durability.

Plasma-Based Surface Treatments

Plasma treatment modifies the plastic’s surface at the molecular level without adding any coating. It’s like giving the surface a chemical makeover that makes it hostile to plasticizer migration.

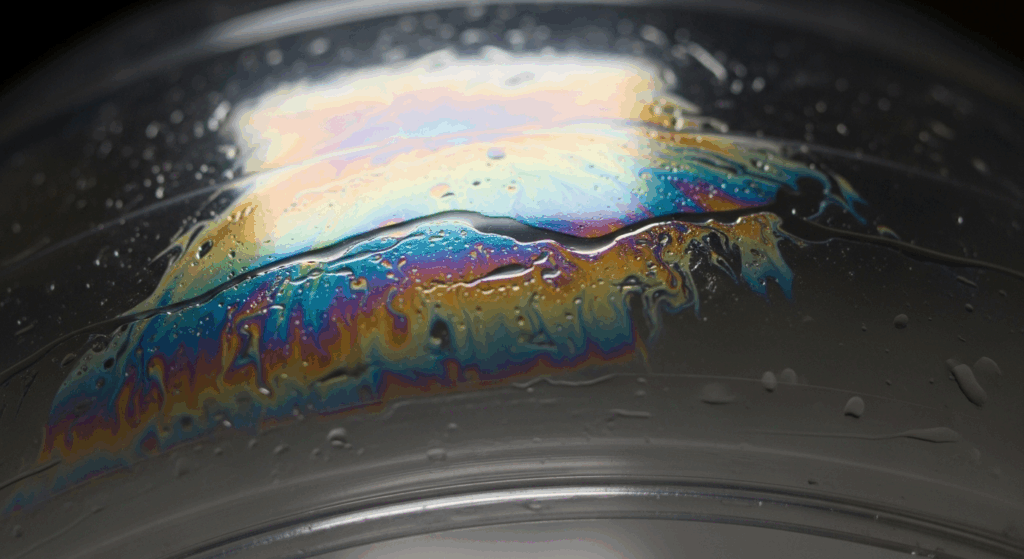

The process bombards the surface with ionized gas. This breaks chemical bonds and creates new ones, forming a dense, cross-linked skin just nanometers thick. Plasticizers can’t penetrate this modified layer easily.

Different gases create different effects. Oxygen plasma makes the surface more polar, repelling non-polar plasticizers. Fluorine plasma creates an ultra-low energy surface that nothing wants to stick to.

The treatment takes just seconds and doesn’t change the plastic’s appearance. It’s perfect for medical devices or toys where you need invisible protection.

FAQs

What causes plasticizers to migrate in the first place?

Plasticizers migrate because they’re not chemically bonded to the polymer – they’re just mixed in. Heat, mechanical stress, and contact with other materials all speed up their movement to the surface where they can escape.

Can you completely stop plasticizer migration?

Yes, but only through internal plasticization where flexible groups are chemically bonded to the polymer. All other methods significantly reduce migration but can’t eliminate it entirely. The goal is usually to reduce it to safe, acceptable levels.

How do I know if plasticizer migration is happening?

Look for a sticky or oily film on the plastic surface, a strong chemical smell, or discoloration. In flexible plastics, you might notice the material becoming brittle or cracking as plasticizers escape over time.

Are migrated plasticizers dangerous?

It depends on the specific plasticizer and exposure level. Some older plasticizers like certain phthalates are endocrine disruptors. Modern alternatives are generally much safer, but minimizing migration is always the best practice, especially in food contact or medical applications.

Which method is most cost-effective for reducing migration?

Using HMW plasticizers is usually the most economical first step since it only requires switching chemicals, not equipment. Surface treatments like plasma modification offer excellent results for the cost when you need better performance than HMW plasticizers alone can provide.