Bending a half-inch PVC pipe takes about 2 minutes. Bending a 6-inch pipe? Over an hour. That dramatic scaling tells you everything about what you’re getting into with DIY pipe bending.

For pipes 2 inches and smaller, bending PVC at home is straightforward. You need to heat the pipe to 210-275F, prevent kinks with sand or a bending spring, and understand one critical limitation: bent PVC should never be used for pressurized water lines.

This guide covers the exact temperatures, timing, and techniques to bend PVC pipe safely for garden structures, custom conduit runs, or any DIY project requiring curved pipe.

What Temperature Do You Need to Bend PVC Pipe?

Heat PVC to between 210 and 275F for bending. This temperature range makes the pipe soft enough to shape while keeping it controllable.

Below 200F, PVC remains too rigid and may crack under stress. At 350F, the material becomes viscous and floppy, making precise bends nearly impossible. At 425F, PVC carbonizes and burns.

The specific temperature within that range depends on your bend angle:

- Minor bends (under 30 degrees): 225F works well, even without internal support

- Sharp bends (over 30 degrees): Use 250-275F and always add internal support to prevent wall collapse

Hotter is not better. Many beginners crank up the heat thinking faster is easier. The opposite is true. Overheated PVC becomes so soft it kinks and collapses before you can shape it. Aim for the lower end of the range and add heat gradually if the pipe isn’t softening.

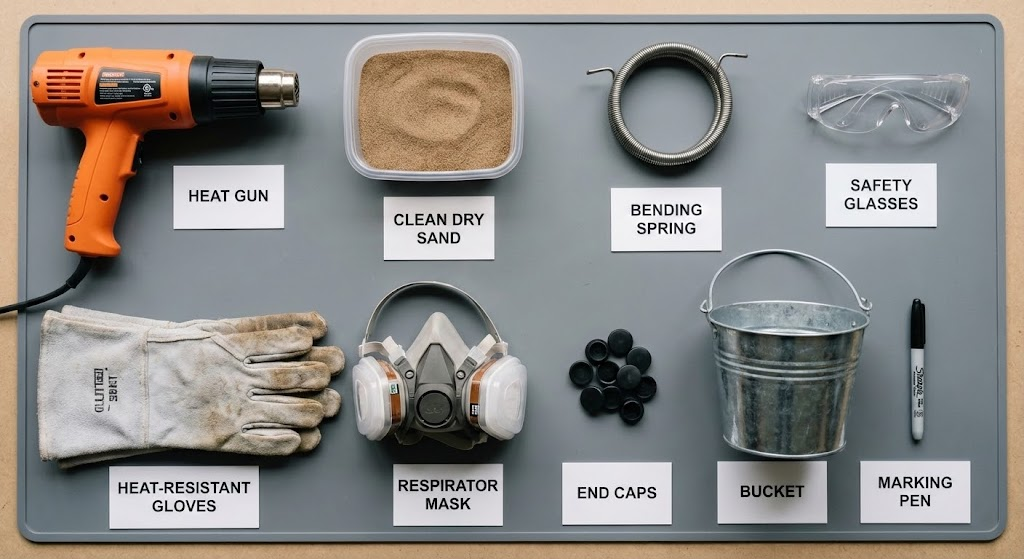

What Tools and Materials Do You Need?

You need a heat source, something to prevent kinks, and safety gear. Here’s the complete list:

Heat Sources (choose one):

- Heat gun with adjustable temperature (set to 350-400F)

- Oven (for the heated sand method)

- Large pot for boiling water (limited effectiveness)

Kink Prevention (choose one):

- Clean, dry sand

- PVC bending spring (sized 1-2 mm smaller than pipe inner diameter)

- Flexible metal conduit (greenfield)

Safety Equipment:

- Heat-resistant gloves

- Safety glasses

- Respirator mask (recommended, not optional for indoor work)

- Fire extinguisher nearby

Additional Items:

- End caps or tape to seal pipe ends (for sand method)

- Bucket of cold water (to set bends quickly)

- Marking pen to identify bend locations

- Jig or form for consistent angles

A basic heat gun costs between $20 and $40 and pays for itself after two or three projects compared to buying fittings for every bend.

How Do You Prevent PVC Pipe from Kinking When Bending?

Fill the pipe with sand or insert a bending spring before heating. Without internal support, sharp bends will collapse the pipe wall inward, creating an unusable kink.

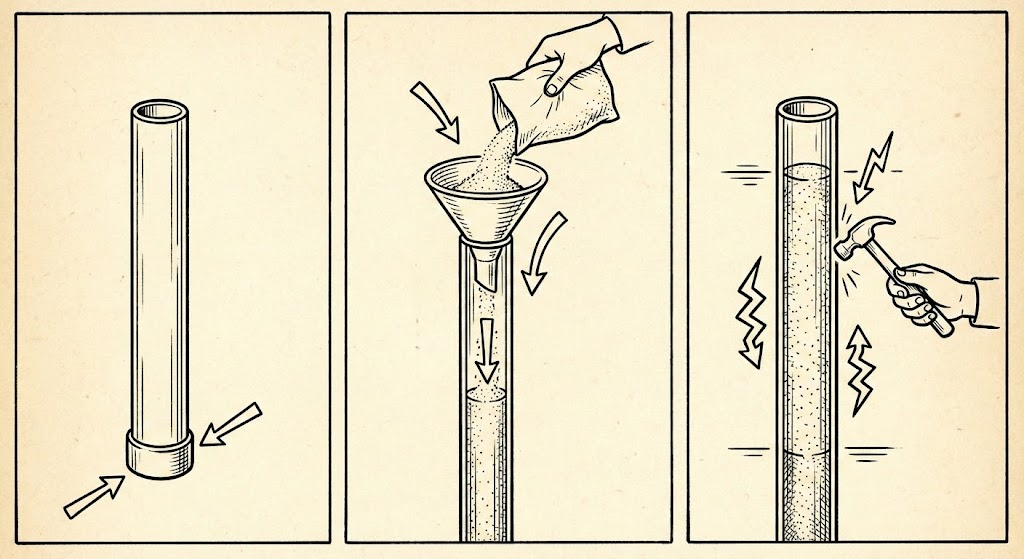

Sand Method:

- Cap or tape one end of the pipe

- Pour clean, dry sand through the open end

- Tap the pipe against the ground to settle the sand densely

- Cap the other end

- Heat and bend as normal

The sand creates a tight, packed core that distributes force evenly across the pipe wall. After bending, remove the caps and pour out the sand for reuse.

Bending Spring Method:

Insert a spring sized 1-2 mm smaller than the pipe’s inner diameter. The spring allows some compression while preventing the dramatic collapse that causes kinks. The sizing gap is critical: too tight and you won’t get it out after bending.

Which Method Works Better?

For most DIY projects, sand offers more consistent results. Springs work well for simple bends but can be frustrating to remove, especially on tighter curves where the spring gets wedged. Sand pours out easily and costs nothing.

Step-by-Step: How to Bend PVC Pipe with a Heat Gun

Follow these steps for clean, consistent bends:

Preparation:

- Mark the bend location on the pipe with a pen

- Fill the pipe with sand or insert a bending spring

- Set your heat gun to 350-400F (the pipe reaches 210-275F when held at proper distance)

- Prepare a bucket of cold water nearby

- Clear your work area of flammable materials

Heating:

- Hold the heat gun 3 to 4 inches above the PVC

- Keep the gun moving constantly in slow passes

- Rotate the pipe to heat all sides evenly

- Continue until the pipe softens along the entire bend area

How long does heating take?

| Pipe Size | Approximate Heating Time |

|---|---|

| 1/2 inch | 2 minutes |

| 3/4 inch | 4 minutes |

| 1 inch | 5 minutes |

| 1-1/4 inch | 6 minutes |

These times assume consistent heat gun application. Larger pipes require significantly more time: 3-4 inch pipes need about 30 minutes, and 6-inch pipes need over an hour.

Bending:

- Once the pipe feels soft and pliable, work slowly

- Apply gentle, even pressure to form the curve

- Use a jig or form for consistent angles

- Hold the position for 30-60 seconds

Setting the Bend:

- While holding the bent position, apply cold water immediately

- Run a wet cloth along the bend or dip it in your water bucket

- Wait 10-30 minutes for complete cooling before putting the pipe under stress

Rushing the cooling phase leads to bends that slowly straighten over time or develop stress fractures.

Alternative Methods: Heated Sand and Boiling Water

Heated Sand Method

Instead of heating the pipe directly, heat the sand first and let it warm the pipe from inside. This method works particularly well for complex shapes or multiple bends in one section.

Process:

- Heat clean, dry sand to about 450F in an oven

- Cap one end of your PVC pipe

- Carefully pour the hot sand into the pipe (use heat-resistant gloves)

- Cap the other end

- Wait until the pipe softens throughout

- Bend to your desired shape

- Cool with water and remove sand

This approach provides more even heating than a heat gun, reducing the risk of hot spots that cause uneven bending or burns.

Boiling Water Method

Immersing PVC in boiling water (212F) can soften it enough for minor bends. Submerge the pipe for approximately 5 minutes, then bend slowly.

However, this method has limitations. Results vary significantly based on pipe wall thickness, and the temperature barely reaches the lower edge of the bending range. For anything beyond gentle curves, the heat gun or heated sand methods produce more reliable results.

What Are the Safety Precautions for Heating PVC?

PVC cannot be extinguished once it ignites. Unlike most plastics, burning PVC does not need oxygen to continue burning. This fact alone should shape how you approach every bending project.

Toxic Fumes:

Heating PVC releases hazardous compounds, especially if overheated:

- Hydrogen chloride (irritates lungs and eyes)

- Vinyl chloride (carcinogenic when burned)

- Carbon monoxide

- Chlorinated furans

These fumes begin forming at temperatures as low as 158F. Work outdoors or in a very well-ventilated area. A respirator mask is not overkill.

Required Safety Gear:

- Heat-resistant gloves (not optional)

- Safety glasses (hot PVC can splatter)

- Respirator with organic vapor cartridges

- Long sleeves (softened PVC sticks to skin and burns)

Fire Prevention:

- Keep a fire extinguisher within arm’s reach

- Clear all flammable materials from your work area

- Never use an open flame to heat PVC

- Never leave heating equipment unattended

- Have water available for cooling and emergencies

If you’re not comfortable working outdoors with proper ventilation, use factory fittings instead. The convenience of indoor work isn’t worth the health risks of breathing PVC fumes.

When Should You Use Fittings Instead of Bending?

Working electricians offer blunt advice: use factory 45 and 90 degree bends wherever possible. Factory fittings come in 22.5, 45, and 90 degree angles. For standard angles, they save time and produce stronger joints.

Choose fittings over bending when:

- Your pipe diameter exceeds 2 inches

- The pipe will carry pressurized water or gas

- You need precise, repeatable angles

- The bend angle exceeds 90 degrees

- You’re working on plumbing that requires code compliance

The strength issue matters:

Bending PVC destroys the uniform molecular structure of the material. The bent area becomes a weak point with reduced pressure ratings. For any application where the pipe experiences internal pressure, bent sections should be considered compromised.

The rule is simple: bent PVC is for routing cables, building garden structures, creating furniture, or any non-pressure application. For pressurized plumbing, use fittings or buy pre-bent pipe rated for the pressure you need.

Pipes larger than 2 inches are genuinely difficult to bend at home. They kink easily and require specialized equipment like compressed air injection or commercial heat blankets to achieve even heating. For these sizes, fittings aren’t just recommended, they’re practically required.

Common Mistakes and How to Avoid Them

Overheating the pipe:

Cranking up the temperature seems logical for faster results. Instead, you get a floppy pipe that kinks before you can shape it. Stay in the 210-275F range at the pipe surface, even if your heat gun reads higher.

Heating too quickly:

Blasting one spot creates a localized soft zone surrounded by rigid pipe. When you try to bend, the soft spot collapses while the rigid sections resist. Move your heat source constantly and rotate the pipe.

Skipping internal support for sharp bends:

Bends over 30 degrees need sand or a spring inside. Without support, the inside wall of the curve buckles. This mistake is easy to make once and never again.

Treating Schedule 80 like Schedule 40:

Schedule 80 PVC has significantly thicker walls (0.179 inches vs 0.133 inches for 1-inch pipe). It requires more heating time and is more difficult to bend uniformly. For DIY bending, Schedule 40 is considerably easier to work with.

Attempting pipes larger than 2 inches:

Standard DIY methods don’t scale well. Large pipes need compressed air inside to maintain their shape and commercial heating equipment to warm them evenly. Accept that fittings are the practical choice for bigger jobs.

Using bent pipe for pressure applications:

Worth repeating: bent PVC has compromised structural integrity. Using it for pressurized water lines risks leaks or failures. The molecular structure changes during bending, and that damage is permanent.

Start Your First Bend

You now have the temperatures (210-275F), the timing (2-6 minutes for common sizes), and the techniques (sand filling, constant heat rotation, immediate cooling) to bend PVC pipe successfully.

Pick your method based on your project: heat gun for quick single bends, heated sand for complex shapes or when working without electricity. Gather your materials, set up outdoors, and start with a scrap piece to calibrate your technique before cutting into your project pipe.