Diethylhexyl phthalate (DEHP) – the most widely used plasticizer for decades – is rapidly disappearing from the market due to regulatory restrictions and health concerns. Manufacturers worldwide must make a choice: find an alternative or face compliance failures, supply chain disruptions, and potential legal liability.

Here’s what you need to know: dioctyl terephthalate (DOTP) has emerged as the leading replacement, offering comparable performance to DEHP while eliminating the regulatory headaches and health risks. This isn’t just a compliance play – it’s a smart business decision that protects your products, your company, and your customers.

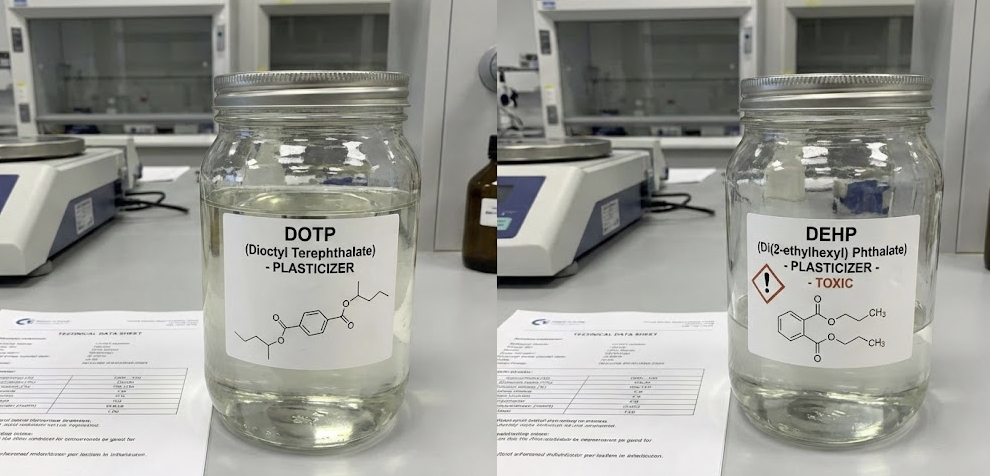

Chemical Structure: Understanding the Key Difference

| Property | DEHP (Diethylhexyl Phthalate) | DOTP (Dioctyl Terephthalate) |

|---|---|---|

| Chemical Structure | Ortho-phthalate (1,2-benzenedicarboxylic acid ester) | Terephthalate (1,4-benzenedicarboxylic acid ester, para-position) |

| Molecular Formula | C₆H₄(CO₂C₈H₁₇)₂ | C₆H₄(CO₂C₈H₁₇)₂ |

| Molecular Weight | 390.56 g/mol | 390.56 g/mol |

| Alcohol Component | 2-ethylhexanol | 2-ethylhexanol |

| Base Acid Type | Ortho-phthalic (smaller, more flexible) | Terephthalic (larger, more rigid) |

| Molecular Size | Smaller, more compact | Larger molecule with additional branching |

Both DEHP and DOTP share the same alcohol component (2-ethylhexanol), but the base acid differs. DEHP comes from ortho-phthalic acid, while DOTP comes from terephthalic acid. This seemingly small structural difference creates profound differences in behavior.

The larger size of DOTP’s terephthalic structure has a critical advantage: the molecule doesn’t easily escape from plastic materials. Smaller, more compact molecules like DEHP can migrate out of polymers, leaching into food, water, or the environment. DOTP’s bigger structure gets trapped within the polymer matrix, staying put even under stress or heating.

This structural difference explains why DOTP has become the go-to replacement for DEHP. It delivers similar plasticizing performance while eliminating the migration problem that haunts DEHP.

Safety Profile: Why DEHP is Facing Restrictions

The health concerns surrounding DEHP aren’t new theories or speculation. They’re well-documented in peer-reviewed research spanning decades, documented by regulatory agencies worldwide, and confirmed through countless human studies.

DEHP is classified as an endocrine disruptor – a chemical that interferes with hormone systems. It doesn’t just sit passively in your product; it leaches out and enters the human body through ingestion, inhalation, and dermal contact. Once inside, it disrupts the normal functioning of hormonal systems.

DOTP: The Safer Alternative

DOTP offers a compelling contrast to DEHP’s concerning health profile. The safety data is stark: DOTP has a NOAEL (no observable adverse effect level) of 500-700 mg/kg in animal studies, compared to DEHP’s NOAEL of just 4.8 mg/kg.

That’s a 100 to 140-fold safety margin.

To put that in perspective: in laboratory animals exposed to high doses, scientists couldn’t detect any adverse effects from DOTP until reaching doses 100+ times higher than the DEHP threshold where harm appears. This isn’t marginally safer – it’s substantially safer.

Performance Comparison: DOTP Holds Its Own

The key question manufacturers ask: does DOTP match DEHP’s performance? The short answer is yes – in most applications, DOTP performs equally well or better than DEHP.

| Performance Metric | DEHP | DOTP | Winner |

|---|---|---|---|

| Thermal Stability | Moderate; vaporizes at 323°C | Excellent; significantly higher thermal stability | DOTP |

| Heat Resistance | Good within temperature limits | Superior; maintains flexibility at elevated temperatures | DOTP |

| Cold-Temperature Flexibility | Adequate; some brittleness at low temps | Better; flexible even in cold conditions | DOTP |

| Volatility | Moderate; some emissions at elevated temperatures | Very low; minimal volatility or emissions | DOTP |

| Migration Resistance | Poor; readily leaches from polymers | Excellent; minimal migration | DOTP |

| Outdoor Weatherability | Fair; degrades under UV exposure | Good; better UV resistance | DOTP |

| Electrical Properties | Good; adequate insulation | Good; equivalent insulation properties | Tie |

| Mechanical Flexibility | Good; maintains adequate pliability | Good; comparable flexibility profile | Tie |

| Processing Efficiency | Excellent; processes smoothly | Good; requires slightly longer processing times | DEHP |

| Long-Term Durability | Fair; degrades over time | Excellent; maintains properties longer | DOTP |

The comparison reveals an important pattern: DOTP actually outperforms DEHP in applications where stability and durability matter most. Wire insulation, medical tubing, and products exposed to heat or environmental stress all benefit from DOTP’s superior thermal stability and resistance to degradation.

Where DEHP maintains an edge is in processing speed – some manufacturing processes run slightly faster with DEHP. But this advantage is marginal and often more than offset by DOTP’s other benefits.

In medical device applications specifically, manufacturers increasingly prefer DOTP because it maintains its properties longer, resists degradation better, and doesn’t leach into patients’ bloodstreams.

Cost-Benefit Analysis

Let’s be direct about the economics: DOTP costs more than DEHP. It always has, and likely always will.

While specific commodity prices fluctuate, DOTP typically costs 15-25% more than DEHP on a per-kilogram basis. For a product containing 30% plasticizer by weight, that premium translates to roughly 5-7% higher material costs.

Manufacturing Considerations: Making the Switch

Switching from DEHP to DOTP requires more than just specifying a different chemical. Your manufacturing process, equipment, and formulation all need to be evaluated and potentially adjusted.

PVC Compatibility

The good news: DOTP is compatible with PVC. It’s not a perfect substitution where you can simply swap chemicals, but it integrates successfully into PVC formulations.

The compatibility works because of that similar molecular structure. Both DEHP and DOTP have similar polar-nonpolar balance, which determines how well a plasticizer dissolves and distributes throughout the PVC resin. DOTP achieves adequate compatibility, though the balance is slightly different from DEHP.

However, formulations designed for DEHP may need adjustment for DOTP. You might need to modify:

- Plasticizer concentration: Some formulations perform better with 32-35% DOTP instead of exactly 30% DEHP

- Resin selection: Certain PVC resins work better with DOTP than others

- Stabilizer packages: The stabilizer additives that protect PVC during processing may need adjustment

- Other additives: Processing aids, thickeners, and other additives sometimes require recalibration

Processing Temperature Requirements

DOTP’s higher thermal stability is actually an advantage here. Processing temperatures can remain the same or can even be reduced slightly with DOTP, since it doesn’t degrade as readily at elevated temperatures.

The practical implication: your existing equipment can process DOTP without major modifications. You don’t need new extruders, calendars, or injection molding machines.

Formulation Adjustment Process

Making the switch requires careful formulation work:

- Lab-scale testing: Start with small batches, replacing DEHP with DOTP at similar concentrations (typically 28-35% by weight)

- Property evaluation: Test the resulting compound for tensile strength, elongation, tear resistance, and any application-specific properties

- Processing trials: Run small production batches to evaluate processing performance, cycle times, and product consistency

- Long-term aging tests: Expose DOTP-formulated products to heat, light, and chemical conditions your end-use product faces to confirm long-term stability

- Regulatory/certification testing: If your product requires certifications (medical device, food contact, electrical), you’ll need to conduct the appropriate testing with the new formulation

This process typically takes 3-6 months from initial trials to full production implementation.

Decision Framework: Choosing Your Path Forward

Making the decision to switch from DEHP to DOTP shouldn’t be arbitrary. A structured evaluation helps you determine what makes sense for your specific situation.

Step 1: Assess Your Regulatory Exposure

Ask these questions:

- Does your product category fall under DEHP restrictions in your target markets?

- Are your customers in the EU, US, or other regulated regions?

- Do your products come into contact with food?

- Are your products marketed to children or used in childcare?

- Do your products reach hospitals or medical facilities?

If you answered yes to any of these, regulatory pressure favors DOTP now, not eventually.

Step 2: Evaluate Performance Requirements

Consider your application’s specific demands:

- What temperature range does your product operate within?

- How important is thermal stability and long-term durability?

- What mechanical properties (flexibility, tensile strength, tear resistance) are critical?

- How sensitive is your product to plasticizer volatility or migration?

- Do you need proven, established performance data or can you accept emerging alternatives?

Applications demanding high thermal stability or long-term reliability favor DOTP for its superior performance.

Step 3: Calculate True Cost of Switching

Don’t just look at material cost. Calculate total switching costs:

- Material cost premium: 5-7% higher product cost

- R&D and formulation: 3-6 months of testing and formulation work

- Production trials: Downtime and rework during transition

- Regulatory testing: If required for your product category

- Supply chain setup: Establishing DOTP supplier relationships

Against this, weigh the avoidance of:

- Compliance costs: Reduced testing, certification, documentation

- Regulatory risk: Protection against future restrictions

- Market access: Customers demanding phthalate-free products

- Liability: Reduced exposure to future health concerns

For most manufacturers, the total cost of switching becomes justified within 2-3 years through risk reduction and market access improvements.

Step 4: Assess Your Supply Chain Flexibility

Can your supply chain handle DOTP adoption?

- Do you have production capacity to conduct formulation trials?

- Can you manage DOTP sourcing from limited suppliers?

- Can you adjust manufacturing processes if needed?

- Do you have time to plan the transition or is regulatory urgency forcing rapid change?

Manufacturers with flexible supply chains can transition gradually. Those facing urgent regulatory deadlines need to accelerate.

Step 5: Consider Your Competitive Position

Think strategically:

- Are competitors already using DOTP or other alternatives?

- Are your customers requesting phthalate-free products?

- Would switching to DOTP give you a competitive advantage?

- Could staying with DEHP become a competitive disadvantage?

In many industries, DOTP adoption has become a market expectation. First-movers gain credibility and customer loyalty. Laggards face customer pressure and potential market access restrictions.