If you’re involved in plastic manufacturing, materials procurement, or product development, you’ve likely faced a tough decision: stick with DINP or switch to DINA. Both plasticizers deliver flexibility and durability to PVC products, but they’re fundamentally different chemicals with very different implications for your business.

Here’s the reality: DINP (diisononyl phthalate) has been the industry standard for decades. It’s cheap, widely available, and performs exceptionally well. But in January 2025, the EPA issued a final risk evaluation determining that DINP presents an unreasonable risk to human health. DINA (diisononyl adipate), meanwhile, is a non-phthalate alternative that’s gaining traction as regulations tighten globally.

The question isn’t just “which is better?” It’s “which is right for your specific application, your regulatory environment, and your risk tolerance?” This guide walks you through the critical differences so you can make an informed decision.

What Are DINA and DINP?

DINA and DINP sound similar, but they’re chemically distinct compounds with different safety profiles and regulatory trajectories.

DINP: Diisononyl Phthalate

DINP is a high molecular weight ortho-phthalate used as a flexible PVC plasticizer. It’s an almost colorless, odorless oily liquid that’s extremely common in industrial applications.

DINP emerged as a replacement for earlier phthalates like DOP (dioctyl phthalate) because it offered better performance with lower volatility. Manufacturers found they could reduce fume emissions during processing while improving product permanence—meaning the plasticizer stays in the product rather than migrating out over time.

DINA: Diisononyl Adipate

DINA is a non-phthalate plasticizer made from adipic acid rather than phthalic acid. Like DINP, it’s a colorless liquid with faint odor and oily consistency. The key difference is structural: DINA is an adipate ester, not a phthalate.

DINA emerged as manufacturers sought safer alternatives to phthalates, particularly for sensitive applications like toys, medical devices, and food packaging. It delivers comparable flexibility and durability to DINP without the phthalate structure that regulators increasingly scrutinize.

The distinction matters because it affects not just safety, but also how different regulatory bodies treat each chemical. DINA is permitted in food contact materials in North America and parts of Asia, while DINP faces restrictions in these same applications.

Chemical Structure and Physical Properties: What’s the Difference?

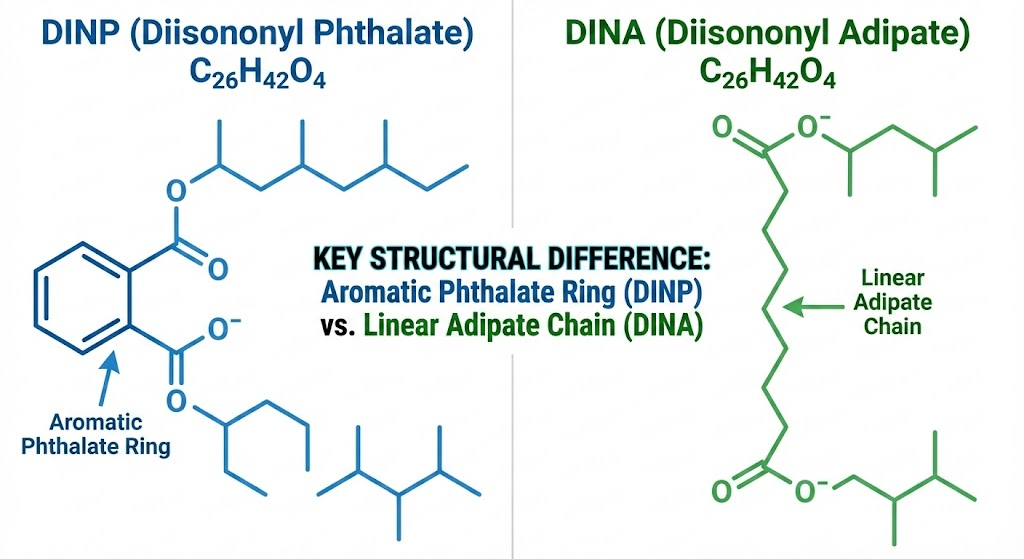

The fundamental difference between DINA and DINP lies in their chemical backbone, which cascades into different performance and safety characteristics.

Molecular Composition Differences

DINP is an ester of phthalic acid with isononyl alcohols. Its structure contains a benzene ring with two carboxyl groups attached (the characteristic phthalate structure), and these groups bond to branched nine-carbon chains. This aromatic benzene core is what makes it a phthalate.

DINA is an ester of adipic acid with the same isononyl alcohols. Adipic acid is a six-carbon chain with carboxyl groups at each end—no aromatic ring. This fundamentally different structure is why DINA avoids the phthalate classification entirely.

Why does this matter? Phthalates are known endocrine disruptors and have faced increasing regulatory restrictions globally. By using an adipate backbone instead, DINA sidesteps many of these concerns. The regulatory red flags that follow phthalates don’t apply to adipate esters.

Physical Properties Comparison

Both plasticizers share similar practical characteristics that make them useful for industrial applications:

| Property | DINP | DINA |

|---|---|---|

| Appearance | Colorless, oily liquid | Colorless, oily liquid |

| Odor | Nearly odorless | Faint intrinsic odor |

| Volatility | ~50% less volatile than DOP | Very low volatility |

| Freezing Point | ~-65°C (approximate) | ~-65°C |

| Boiling Point | High (above 300°C) | Above 232°C (transitions to gas state) |

| Water Solubility | Practically insoluble | Practically insoluble |

| Density | Higher than water | Lower than water (floats) |

The similarity in freezing points explains why both work well in low-temperature applications. The key difference emerges in volatility: both are remarkably stable under normal storage and processing conditions, but DINP shows slightly higher volatility than DINA, meaning it can escape into the air more readily during manufacturing.

Performance Characteristics: How Do They Compare?

For most manufacturers, performance is the immediate concern. Do these plasticizers deliver the flexibility, durability, and processing efficiency you need?

Temperature Performance

Both DINA and DINP excel at maintaining flexibility across temperature ranges, which is exactly why they dominate flexible PVC manufacturing.

DINA’s strength is low-temperature flexibility. When you need products that stay supple in freezing conditions—think of wire insulation in northern climates or outdoor hoses—DINA delivers exceptional cold performance. It prevents the brittleness that makes some plasticizers crack at -20°C or colder.

DINP’s advantage is thermal stability. It resists degradation at higher processing temperatures better than many alternatives. During high-temperature extrusion or injection molding, DINP maintains its properties more consistently. It also resists discoloration from heat exposure better than some competitors.

Both plasticizers are stable well beyond typical processing conditions. DINP maintains stability at higher temperatures, while DINA shows superior resistance to volatility—it doesn’t escape as a gas at elevated processing temperatures.

Processing Efficiency

This is where DINP has historically dominated manufacturing decisions.

DINP reduces melt viscosity by up to 21% compared to DOP, which translates directly to manufacturing efficiency. Lower viscosity means lower die pressure during extrusion. For manufacturers processing high volumes, this reduces wear on equipment and can increase production throughput without requiring new machinery.

During processing, DINP creates about 50% less fume emissions than DOP. For factories running long production shifts, this means better air quality and reduced worker exposure to volatile organic compounds. It’s not just a health benefit—it’s a regulatory compliance advantage that reduces the need for extensive ventilation systems.

DINA performs similarly in processing but doesn’t show the same dramatic efficiency gains. Where DINP shines is in optimizing existing production lines with minimal capital investment. You swap in DINP, and production improves without major changes.

Durability and Permanence

Here’s a critical consideration for products that need to stay flexible throughout their lifespan: does the plasticizer stay in the product or migrate out?

DINA excels at permanence. It resists migration into food, water, or other solvents, which is why it’s approved for food contact materials in many jurisdictions. When you wrap food in PVC film containing DINA, very little plasticizer migrates into the food itself.

DINP shows moderate permanence—better than older phthalates but not as permanent as DINA. In food contact applications, some DINP can extract into fatty foods over time. This migration isn’t necessarily catastrophic (the amounts are typically well below regulatory limits), but it explains why DINP faces restrictions in food contact materials in the EU.

For products that won’t contact food or other extracting substances—automotive cables, wire insulation, building membranes—both plasticizers maintain performance for years or decades. The permanence difference matters most in food contact, personal care, and medical device applications.

Cost

Price and supply chain are practical realities that affect procurement decisions.

DINP is significantly cheaper than DINA, generally 15-30% less expensive depending on market conditions and purchase volumes. This cost advantage stems from DINP’s established manufacturing infrastructure, economies of scale, and lower raw material costs (phthalic anhydride is cheaper to produce than adipic acid).

How to Choose Between DINA and DINP: A Decision Framework

The choice isn’t about which is objectively “better”—it’s about which fits your specific situation.

Step 1: Identify Your Product Category and Geographic Markets

Start by understanding what you make and where you sell it.

If your products are toys, childcare items, medical devices, or food contact materials, DINP is either restricted or facing restrictions. Your decision is made: switch to DINA or equivalent non-phthalate plasticizers.

If your products are automotive, cables, building materials, or industrial components sold primarily in regions with lenient phthalate regulations, DINP remains viable from a regulatory perspective (at least in the short term).

Step 2: Assess Regulatory Requirements by Geography

Regulations differ dramatically by jurisdiction. Where you sell matters as much as what you make.

- EU markets: Assume DINA (non-phthalates) are preferred. DINP faces ongoing restriction risk, and some retailers require phthalate-free claims.

- North American markets: DINP remains legal in most applications, but the EPA’s 2025 determination accelerates the shift toward DINA. Proactive companies are switching now.

- Asian markets: Regulations vary by country. Check specific requirements for each market you serve.

- China: Generally more permissive than EU/US, but shifting toward stricter standards in toys and children’s products.

Step 3: Evaluate Health and Safety Priorities

Consider your company’s risk tolerance and brand positioning.

If you serve health-conscious consumers, premium markets, or regulated industries (medical, pharmaceutical), DINA’s superior safety profile becomes a marketing advantage and risk mitigation strategy.

If you compete on cost and serve price-sensitive markets, DINP’s lower cost might offset safety concerns from a business perspective—though this calculus changes if regulations shift quickly.

Step 4: Compare Performance Requirements

Examine whether DINP’s performance advantages justify its other drawbacks for your specific application.

- High-volume production where viscosity reduction saves money: DINP’s efficiency gains matter.

- Low-temperature applications: Both perform well, slight edge to DINA.

- Processing efficiency isn’t critical: DINA’s performance suffices without the regulatory risk.

- Food contact or high-permanence applications: DINA’s migration resistance is important.

Step 5: Analyze Cost and Supply Chain Implications

Calculate the total impact, not just raw material costs.

Compare scenarios:

- Scenario A: Use DINP today (lower cost), potentially re-formulate in 2-3 years if regulations tighten (re-formulation cost: $50K-$500K+ depending on product complexity).

- Scenario B: Switch to DINA today (higher material cost now), avoid re-formulation risk (savings: avoid future re-formulation costs, reduce regulatory risk, improve brand positioning).

For most manufacturers, Scenario B is economically rational over a 5-10 year horizon.

Application-Specific Recommendations

| Product Type | Recommended Choice | Timing | Key Factors |

|---|---|---|---|

| Toys & Childcare | DINA | Now | Regulatory mandates; no DINP option |

| Food Contact Materials | DINA | Now | Regulatory approval; permanence matters |

| Medical Devices | DINA | Now | Industry standard; biocompatibility |

| Automotive Cables | DINP (for now) | Monitor | Cost advantage; regulatory pressure building |

| General Cable & Wire | DINP or DINA | 2-3 years | Plan transition; cost matters now |

| Building Materials | DINP (for now) | 2-3 years | Cost-driven market; plan exit strategy |

Conclusion

DINA and DINP both deliver flexibility and durability to PVC, but they represent different eras of chemical decision-making.

DINP is the legacy choice—cost-effective, widely available, and proven across decades of industrial use. But it carries increasing regulatory and health risk. The EPA’s January 2025 determination marks a turning point: regulators no longer consider the traditional “safety margins” adequate justification for continued DINP use.

DINA is the emerging standard—more expensive upfront, but non-phthalate, better-positioned for future regulations, and increasingly approved in sensitive applications. For toys, medical devices, and food contact materials, DINA is already the practical requirement. For other applications, DINA is the safe bet.

Your decision depends on your specific application, markets, and tolerance for regulatory risk. But the trajectory is clear: the industry is moving toward non-phthalates. The question is whether you lead that shift or follow it after facing restrictions.