DEHP restrictions are reshaping PVC formulation requirements across industries. If you’re a plastics manufacturer or compounder, you’ve probably noticed the shift. Regulations are tightening. Customers are asking questions. And you’re left wondering which alternative plasticizer actually works for your applications.

Here’s the problem: choosing the wrong DEHP replacement can wreck your formulations. I’ve seen manufacturers waste months reformulating products because they picked a plasticizer based on marketing claims rather than technical data. The costs add up fast—failed batches, compliance headaches, and lost customer trust.

DINA (Diisononyl Adipate) keeps coming up as an alternative. But how does it actually stack up against DEHP in real-world PVC applications? That’s exactly what we’re going to break down.

What Are DINA and DEHP?

What Is DEHP?

DEHP (Di-2-ethylhexyl phthalate) is the plasticizer that built the flexible PVC industry. It’s an ortho-phthalate ester with an aromatic ring structure, and it’s been the go-to choice for decades.

Why? Three reasons: cost, performance, and availability.

DEHP delivers consistent plasticizing efficiency. The industry literally uses it as the benchmark—DEHP’s efficiency rating is set at 1.0, and every other plasticizer gets measured against it. When you’re comparing alternatives, you’re comparing them to DEHP.

But here’s what changed everything: health concerns. DEHP is now classified as a reproductive toxicant in the EU. It’s an endocrine disruptor. And regulators worldwide have responded with restrictions that are only getting tighter.

What Is DINA?

DINA (Diisononyl Adipate) is a non-phthalate plasticizer built for one specific job: low-temperature flexibility.

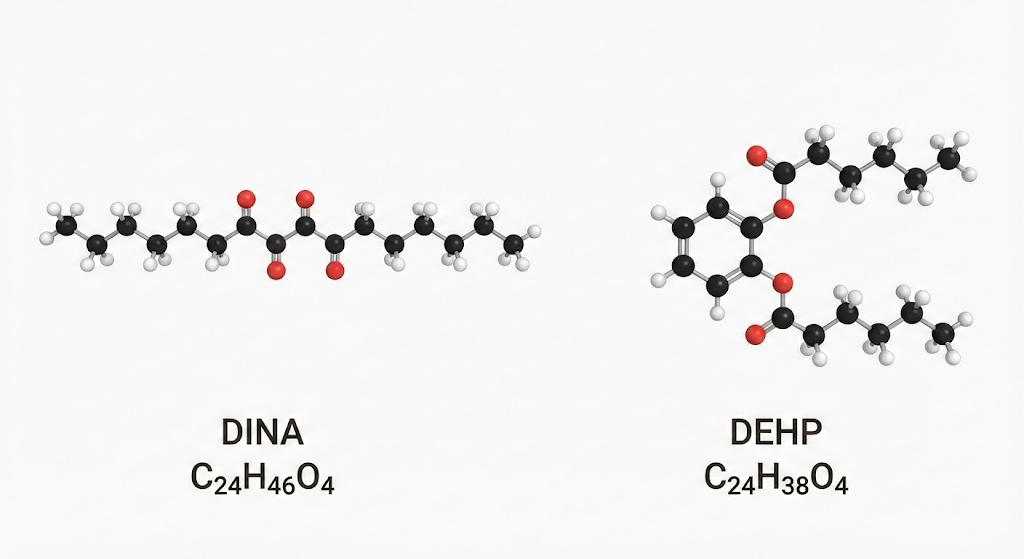

The chemistry matters here. DINA (CAS 33703-08-1) is an adipate ester with a linear aliphatic structure. That’s fundamentally different from DEHP’s aromatic ring. This linear structure is why DINA excels where DEHP struggles—when temperatures drop.

The key difference? DINA doesn’t carry the same health baggage. It’s generally unrestricted, approved for food contact, and suitable for sensitive applications like toys and medical devices. That regulatory clearance opens doors that DEHP now closes.

How Do DINA and DEHP Compare in Technical Performance?

Chemical and Physical Properties Comparison

Let’s get into the specs. Both plasticizers share a similar molecular weight, but their structures create very different performance profiles.

| Property | DINA | DEHP |

|---|---|---|

| CAS Number | 33703-08-1 | 117-81-7 |

| Molecular Formula | C24H46O4 | C24H38O4 |

| Chemical Family | Adipate ester | Phthalate ester |

| Structure | Linear aliphatic | Aromatic ring |

| Appearance | Clear, colorless liquid | Colorless, oily liquid |

| Odor | Mild, characteristic | Nearly odorless |

| Solubility | Miscible with organic solvents | Oil-soluble, not water-soluble |

DINA’s linear molecular structure gives it lower viscosity than DEHP. That affects how it processes and how it performs in your final product. The linear chains move more easily at low temperatures, which is exactly why adipates beat phthalates in cold-weather applications.

Plasticizing Efficiency: Which Delivers Better Flexibility?

DEHP sets the standard at 1.0 efficiency. DINA performs similarly to DOA (dioctyl adipate), which means you’ll need roughly the same loading levels to hit your target hardness.

Here’s what that looks like in practice. To achieve 75 Shore A hardness, DEHP typically requires about 32% loading. DINA falls in a similar range, though you might need slight adjustments depending on your specific formulation.

The real efficiency question isn’t about raw numbers—it’s about what properties matter for your application. If you need low-temperature flexibility, DINA’s efficiency at cold temps is actually better than DEHP. If you’re making general-purpose flexible PVC for room-temperature use, they’re roughly equivalent.

Elongation at break follows predictable patterns for both. At 40 phr loading, expect around 215% elongation. Bump that to 60 phr, and you’re looking at 280%. These numbers stay consistent whether you’re using DINA or DEHP.

Migration and Volatility: Understanding the Trade-offs

Here’s where DINA shows its weakness: migration.

DEHP has a diffusion coefficient of 2.72-10.1 × 10⁻¹⁰ cm²/s in PVC. That’s relatively low migration. Adipates, including DINA, migrate faster because their linear structures move more easily through the polymer matrix.

Temperature accelerates migration for both plasticizers. Expect about a 50% increase in migration rate when you go from 25°C to 50°C. At 80°C and above, the process speeds up dramatically.

What does higher migration mean practically? Your DINA-plasticized products may lose flexibility faster over time. Surface bloom can occur. And when PVC contacts other materials—especially other plastics—the plasticizer can transfer and cause problems like stress cracking in the adjacent material.

When Should You Choose DINA Over DEHP?

Applications Where DINA Is the Better Choice

DINA makes sense when any of these conditions apply:

- Cold-weather products. Automotive interiors, refrigeration gaskets, cold-storage equipment—anything that needs to stay flexible below -30°C. DINA’s low-temperature performance is unmatched by DEHP.

- Food contact materials. DINA is approved for food contact applications in major markets. DEHP faces restrictions that make it unsuitable for food packaging in the EU, US, and many other regions.

- Children’s toys and childcare articles. Regulations ban DEHP above 0.1% in products children might mouth. DINA faces no such restrictions.

- Medical devices. The medical industry is moving away from DEHP. California’s Toxic-Free Medical Devices Act phases out DEHP in IV bags and tubing by 2030. DINA offers a compliant alternative.

- UV-exposed applications. DINA provides better UV resistance than DEHP. Outdoor products, window profiles, and anything that sees sunlight benefits from DINA’s stability.

- Products for regulated markets. If you’re selling into the EU, you need REACH compliance. If you’re selling children’s products in the US, you need CPSC compliance. DINA makes both easier.

Applications Where DEHP May Still Be Appropriate

DEHP isn’t dead. It still makes sense for certain applications:

- Industrial products without human contact. Underground cable jacketing, industrial hoses, construction materials that won’t contact skin—these applications face fewer regulatory hurdles.

- Cost-sensitive applications in unrestricted markets. Some regions haven’t restricted DEHP. If you’re serving those markets with price-competitive products, DEHP’s lower cost matters.

- High-volume commodity products. When margins are razor-thin and you’re producing millions of units, that 20-50% price premium for DINA adds up fast.

- Applications requiring maximum migration resistance. If your product contacts other plastics or needs to maintain properties for decades, DEHP’s lower migration rate might be worth the regulatory headaches.

What Regulatory Requirements Apply to DINA and DEHP?

DEHP Restrictions: Global Regulatory Landscape

DEHP faces restrictions almost everywhere. Here’s the current landscape:

| Jurisdiction | Regulation | DEHP Limit | Status |

|---|---|---|---|

| EU | REACH Annex XIV | Authorization required | Active |

| EU | RoHS | <0.1% (1000 ppm) | Active |

| US | CPSC | <0.1% in children’s products | Active |

| California | Prop 65 | Warning required | Active |

| California | Medical devices | Phase-out by 2030 | Pending |

| Japan | Various | <0.05% (500 ppm) | Active |

The trend is clear: restrictions are expanding. The European Parliament keeps adding applications to the restricted list. California’s medical device law signals where other states may go. Japan’s stricter limits show that even established markets can tighten further.

Selling DEHP-plasticized products means constant monitoring of regulatory changes. One new restriction can make your inventory unsellable.

DINA Regulatory Status: Why It’s Preferred for Sensitive Applications

DINA’s regulatory picture is much cleaner:

Generally unrestricted. No major market currently restricts DINA use. You won’t wake up to find your products suddenly non-compliant.

Food contact approved. DINA is approved for food contact applications under FDA regulations and EU food contact regulations. This opens the entire food packaging market.

Medical device suitable. As DEHP exits medical applications, DINA offers a viable replacement for many device types. It’s already used in respiratory tubes, catheters, and IV tubing.

Children’s products compliant. No restrictions apply to DINA in toys or childcare articles. You can sell into this entire market without special testing or limitations.

What Are the Limitations of Each Plasticizer?

DEHP Limitations

Be honest about DEHP’s problems:

- Regulatory toxicant classification. The EU classifies DEHP as a reproductive toxicant. That classification drives most of the restrictions you’re dealing with.

- Endocrine disruption concerns. Research links DEHP to hormone disruption. This drives consumer advocacy and retailer policies beyond just regulatory requirements.

- Expanding restrictions. Every year brings new limitations. The trajectory is one-way—toward more restrictions, not fewer.

- Market access barriers. Major brands won’t touch DEHP. If you want to supply Tier 1 automotive, consumer electronics, or medical device companies, DEHP is increasingly disqualifying.

- Public perception. “Phthalate-free” has become a marketing feature. Products containing phthalates face consumer resistance that affects sales.

DINA Limitations

DINA isn’t perfect either:

- Higher cost. That 20-50% premium is real. For cost-sensitive applications, it’s a significant barrier.

- Higher migration. Adipates migrate faster than phthalates. Products may lose flexibility faster over their lifespan.

- Poorer PVC fusion. DINA doesn’t fuse quite as well as DEHP. You may need to adjust formulations and processing conditions.

- Secondary plasticizer tradition. The industry traditionally uses adipates as secondary plasticizers, not primary ones. Finding optimized primary-use formulations may require more development work.

- Supply chain depth. DEHP has decades of supply chain development. DINA’s supply chain is smaller and less mature. During supply disruptions, DINA may be harder to source.

Key Takeaways for PVC Manufacturers

Choosing between DINA and DEHP comes down to your specific situation.

Choose DINA when:

- You need low-temperature flexibility below -30°C

- You’re making products for food contact, children, or medical use

- You’re selling into regulated markets (EU, US, Japan)

- Your customers specify phthalate-free materials

- You want to avoid future reformulation as DEHP restrictions expand

Consider DEHP when:

- You’re making industrial products without human contact

- Cost is the primary driver and you’re in unrestricted markets

- Migration resistance is critical for your application

- You need maximum supply chain stability

The industry is moving toward non-phthalate plasticizers. Regulatory pressure will continue. Consumer demand for phthalate-free products will grow. If you’re planning new product lines or major capacity expansions, building around DINA or other non-phthalate alternatives reduces long-term risk.