Dashboard surfaces can reach 200F (93C) in Florida summer sun. Arizona State University measured 157F (70C) on dashboard surfaces within one hour of parking in direct sunlight. These temperatures far exceed the 80C commonly cited in general formulation guides, and they explain why standard plasticizers fail in automotive interior applications.

Automotive interiors create one of the harshest thermal environments for plasticized PVC. The combination of direct solar load, greenhouse heating, and dark-colored surfaces pushes component temperatures well beyond what most formulators expect. Selecting the right plasticizer requires understanding actual temperature exposure by component location, not relying on generic specifications.

Temperature Requirements by Interior Zone

Not all interior components experience the same thermal stress. Dashboard surfaces exposed to direct sunlight through the windshield see the highest temperatures. Door panels, shaded from direct sun, run 20-30C cooler. Floor components and areas under seats rarely exceed 60-70C even in extreme conditions.

| Component | Measured Field Temps | OEM Test Specs | Minimum Plasticizer Rating |

|---|---|---|---|

| Dashboard/IP surface | 70-93C (157-200F) | 110-120C soak | Trimellitate (105C+) |

| Door panels | 70-80C (158-176F) | 85-95C | DOTP/DINP acceptable |

| Center console | 65-75C (149-167F) | 80-90C | DOTP/DINP acceptable |

| Floor/carpet backing | 55-65C (131-149F) | 70-80C | Standard phthalates |

| Headliner | 60-75C (140-167F) | 85-95C | DOTP/DINP acceptable |

OEM test specifications typically add 15-25C margin above measured field temperatures. This safety factor accounts for worst-case scenarios: black interiors, desert climates, and vehicles parked in direct sun for extended periods. Automotive engineers working in Okinawa have reported instrument panel test specifications at 110C soak, with some OEMs requiring 120C exposure for validation.

Temperature matters beyond immediate thermal stability. Plasticizer migration doubles in speed for every 10C increase in temperature. A plasticizer that migrates acceptably at 70C will migrate four times faster at 90C. This exponential relationship explains why dashboard components develop sticky surfaces in summer months while remaining stable in cooler seasons.

For PVC dashboards, manufacturers typically select modified PVC formulations with glass transition temperatures (Tg) between 70-85C. This ensures the base polymer maintains structural integrity at operating temperatures while the plasticizer provides necessary flexibility.

Plasticizer Selection by Temperature Tier

The molecular structure of a plasticizer determines its heat resistance. Higher molecular weight creates stronger intermolecular forces, reducing volatility and migration. Trimellitates, with their three ester groups instead of two, provide an additional anchor point that sharply improves high-temperature performance.

| Plasticizer | MW (g/mol) | Service Temp | Volatility (130C/3hr) | Heat Aging (135C/48hr elongation) |

|---|---|---|---|---|

| TOTM | 547 | 105C continuous | 0.10% max | >80% retained |

| TINTM | 589 | 105C continuous | <0.10% | >80% retained |

| DTDP | 530 | 95-100C | Low | 60-70% retained |

| DOTP | 391 | 80-85C | Moderate | 40-50% retained |

| DINP | 419 | 75-80C | Moderate-high | 30-40% retained |

| DOP/DEHP | 391 | 70-75C | High | ~20% retained |

The heat aging data reveals why plasticizer selection matters for long-term performance. DOP (DEHP) loses 80% of its elongation after just 48 hours at 135C. Trimellitates retain over 80% under the same conditions. For cable applications, which share similar thermal demands with automotive interiors, regulations require elongation to drop no more than 20% after 168 hours at 135C or 240 hours at 120C. Only trimellitates consistently meet this requirement.

TOTM exhibits vapor pressure below 10^-7 mmHg at 25C, essentially negligible volatility. This explains why trimellitates dominate automotive dashboard applications where fogging and volatile emissions must be minimized.

For components in the 70-85C range, DOTP offers a viable non-phthalate option. DOTP provides superior heat resistance compared to DINP, with a freezing point of -48C for cold-temperature flexibility. However, neither DOTP nor DINP should be used for dashboard surfaces or other components that experience sustained temperatures above 85C.

The TINTM vs TOTM comparison matters for high-temperature applications. TINTM offers slightly higher molecular weight and marginally better low-temperature flexibility, while TOTM provides better compatibility with some stabilizer systems. Both deliver the 105C continuous service temperature required for automotive dashboard applications.

Test Methods for Automotive Interior Compliance

Automotive OEMs specify multiple test methods to verify plasticizer performance. Formulators must understand these standards for formulation development and supplier qualification.

| Standard | Test Type | Conditions | Measures |

|---|---|---|---|

| VDA 278 | VOC/FOG emissions | Thermal desorption + GC-MS | Semi-volatile compounds (n-C14 to n-C32) |

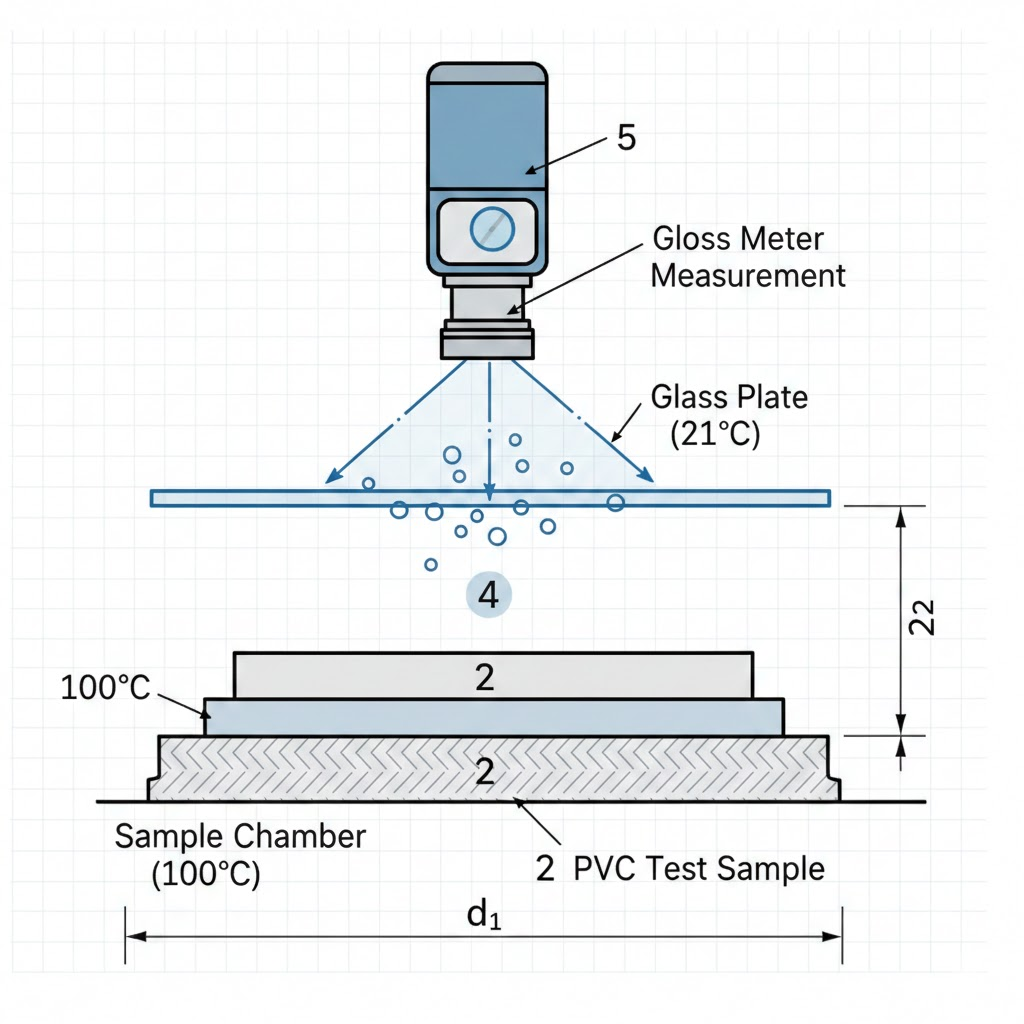

| DIN 75201 / ISO 6452 | Fogging (reflectometric) | 100C/3hr, glass at 21C | Gloss retention on cooled surface |

| DIN 75201 (gravimetric) | Fogging (weight) | 100C/16hr, aluminum foil | Condensate mass |

| SAE J1756 | Fogging characteristics | Photometric + gravimetric | Light scattering deposit |

| VDA 270 | Odor | 3 trained testers | Scale 1-6 (1=not perceptible) |

| ASTM D3045 | Heat aging | Various temp/time | Property retention |

VDA 278 is the German automotive industry standard adopted by Volkswagen, BMW, and Mercedes. It separates volatile organic compounds (VOCs) from semi-volatile fogging compounds (FOG), providing complete emissions data. The FOG test specifically targets plasticizer volatility, measuring compounds with volatilities between n-C14 and n-C32 alkanes.

The DIN 75201 fogging test creates controlled conditions that simulate windshield condensation. The reflectometric method heats samples at 100C for three hours while maintaining a glass plate at 21C above the sample. Gloss measurements on the cooled glass quantify fogging tendency. A DIDP reference sample should yield 77 plus or minus 3% gloss retention for test validation.

OEM-specific standards add additional requirements. GMW 3235 (General Motors) and VW PV 3015 (Volkswagen) specify proprietary test variations and acceptance criteria. Formulators must confirm which standards apply to their target customer base before finalizing plasticizer selection.

Heat aging tests per ASTM D3045 verify long-term thermal stability. Standard automotive testing includes 70C for 168 hours (door panels), 100C for 168 hours (dashboard), and accelerated tests at 120-135C for qualification. Elongation retention, tensile strength, and hardness change are the primary measured properties.

Matching Plasticizer to Application

The 80C temperature limit that appears in many formulation guides assumes moderate ambient conditions and shaded applications. Automotive interiors violate both assumptions. Dashboard surfaces experience greenhouse heating that pushes temperatures 40-50C above ambient, and direct solar exposure creates localized hot spots that exceed even OEM test specifications.

Start plasticizer selection by identifying the component location and its corresponding temperature tier. Dashboard applications require trimellitates. Door panels and consoles can use DOTP or DINP depending on regulatory requirements. Lower-temperature zones can accommodate standard phthalates where regulations permit.

The most reliable approach: request the actual OEM specification document for your target application. Generic temperature ratings from plasticizer suppliers often understate real-world requirements. Testing to VDA 278 or DIN 75201 standards provides objective verification that your formulation meets automotive performance requirements.