Factory and Activities

Industry Applications For Bastone PVC Resin S-800

S-800 is specifically engineered for manufacturers producing ultra-transparent films where optical clarity is paramount. Your film extrusion operations will achieve exceptional transparency levels ideal for premium packaging applications requiring product visibility. The resin's superior clarity characteristics make it the preferred choice for high-end retail packaging and display materials.

Manufacturers of luxury goods packaging choose S-800 for its outstanding visual clarity and surface finish. The material enables your brand clients to showcase their products through crystal-clear packaging that enhances perceived value. Cosmetics packaging producers particularly appreciate the resin's ability to maintain brilliance and transparency over extended shelf life.

Medical Grade and Pharmaceutical Applications

Medical device manufacturers and pharmaceutical packaging companies benefit from S-800's exceptional purity levels and low impurity content. The material's stringent quality controls ensure compliance with healthcare industry standards for sterile packaging and medical component production. Your quality assurance teams can rely on consistent batch-to-batch performance for critical applications.

The resin's controlled residual content and minimal gel particles make it suitable for applications where product safety and regulatory compliance are non-negotiable. Pharmaceutical blister packaging and medical tubing manufacturers depend on S-800's reliable processing characteristics and consistent quality across production runs.

Logistics and Storage Solutions For Bastone PVC Resin S-800

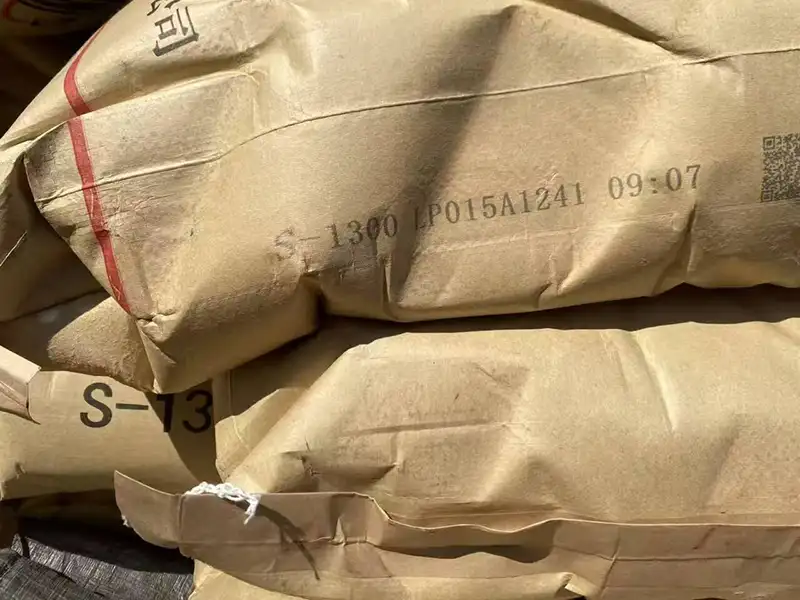

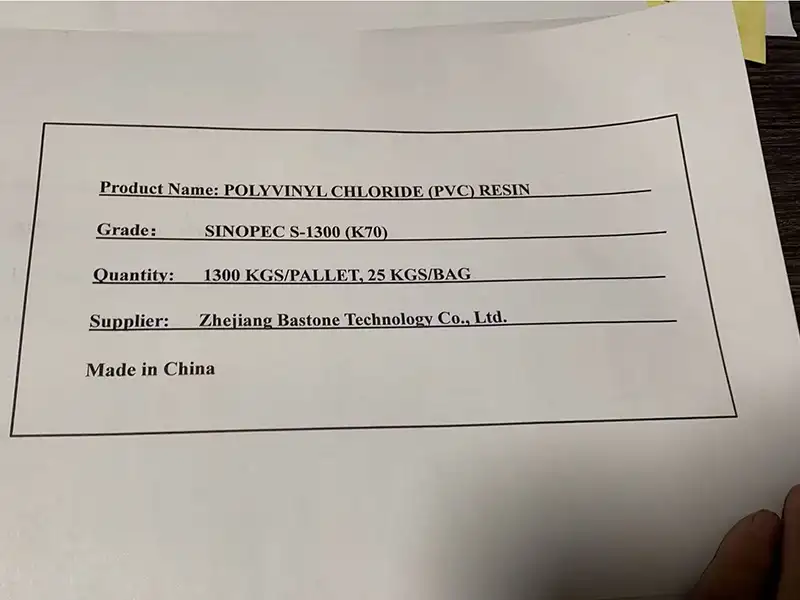

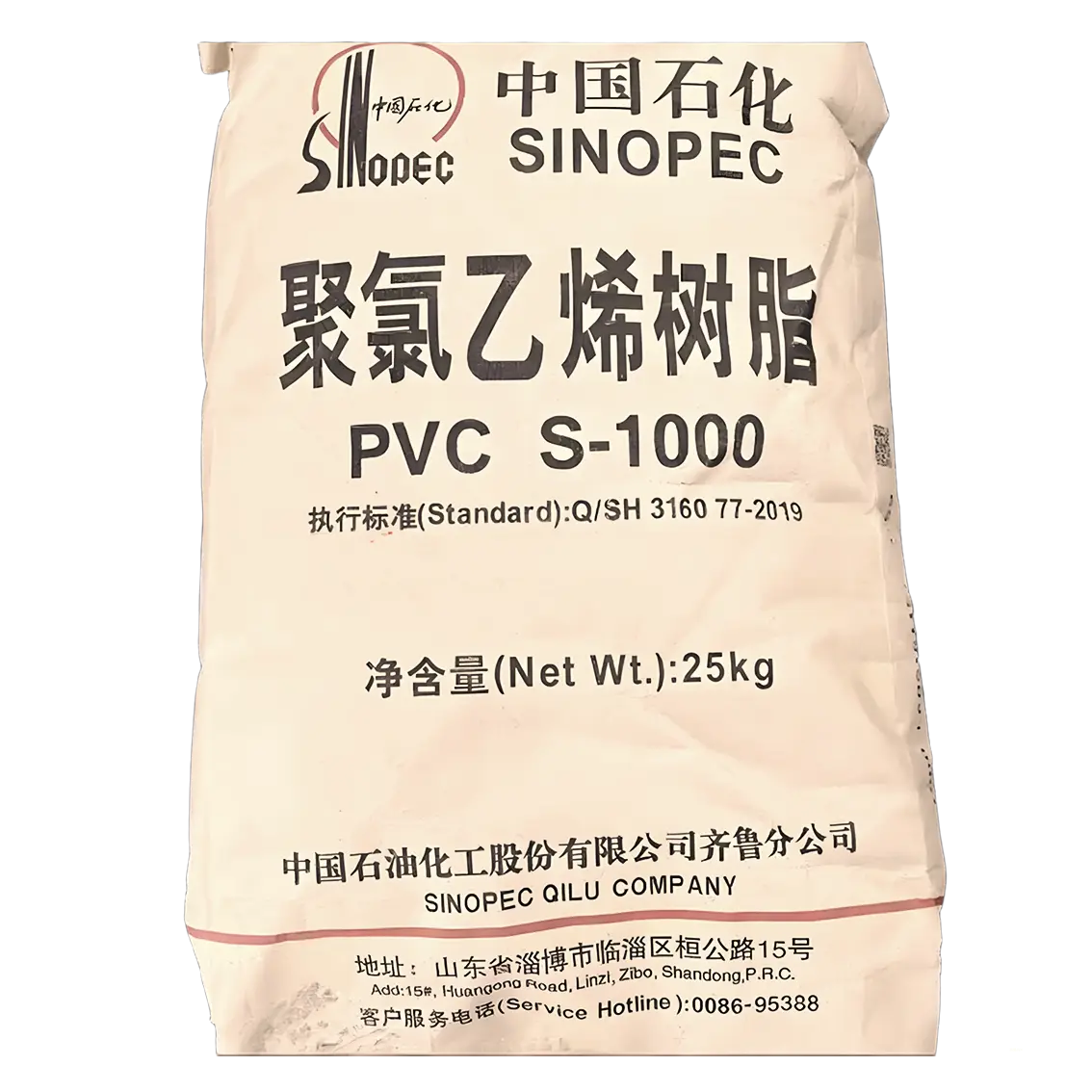

Professional Packaging Standards

Each unit of S-800 PVC Resin is delivered in 25-kilogram composite paper bags meeting national packaging standards. This packaging format optimizes handling efficiency in industrial environments while maintaining product integrity throughout your supply chain.

Handling Requirements for Industrial Operations

Loading and unloading procedures must follow strict industrial safety protocols. Steel hooks and sharp tools are prohibited during material handling to prevent package damage and product contamination. Your receiving operations should utilize appropriate material handling equipment designed for packaged chemical products.