Factory and Activities

Why Choose Bastone PVC Resin-S-1300?

Superior Material Properties

PVC S-1300 resin stands out in the market due to its exceptional polymerization degree of 1250-1350, which directly translates to superior mechanical strength in your final products. This high-grade PVC resin ensures that manufacturers can produce durable, long-lasting items that meet the most demanding industry standards. Whether you're producing pipes, profiles, or injection molded components, the enhanced molecular structure provides the reliability your customers expect.

The apparent density of 0.45-0.52 g/mL makes PVC S-1300 resin ideal for consistent processing and uniform product quality. This consistency reduces production waste and improves your manufacturing efficiency, leading to better cost management and higher profit margins for your business.

Strict Quality Control Standards

PVC S-1300 resin meets the rigorous O/SH3055.77-2007 quality standards, ensuring every batch delivers consistent performance. The residual vinyl chloride monomer content is strictly controlled at ≤2.0 μg/g for Superior grade and ≤5.0 μg/g for Qualified grade, meeting international safety requirements for PVC products. This compliance is crucial for manufacturers targeting export markets or industries with strict regulatory requirements.

The low impurity particle count (≤16 for Superior grade) and minimal "fish eyes" (≤10 per 400cm²) ensure that your finished products have excellent surface quality and appearance. For B2B customers producing high-visibility applications like window profiles or decorative panels, this PVC resin delivers the flawless finish that end users demand.

Excellent End-Product Quality

Products manufactured with PVC S-1300 resin exhibit superior whiteness (≥78% for the Superior grade), providing an ideal base for coloring or maintaining a pristine white finish. This high whiteness value is particularly important for manufacturers producing medical-grade products, food-contact applications, or premium building materials where appearance and purity are critical selling points.

The enhanced impact resistance and mechanical strength of PVC S-1300 resin result in products that withstand harsh operating conditions and have extended service life. Your customers benefit from reduced maintenance costs and fewer replacements, which strengthens your reputation as a supplier of premium quality products.

Competitive Advantages for Your Business

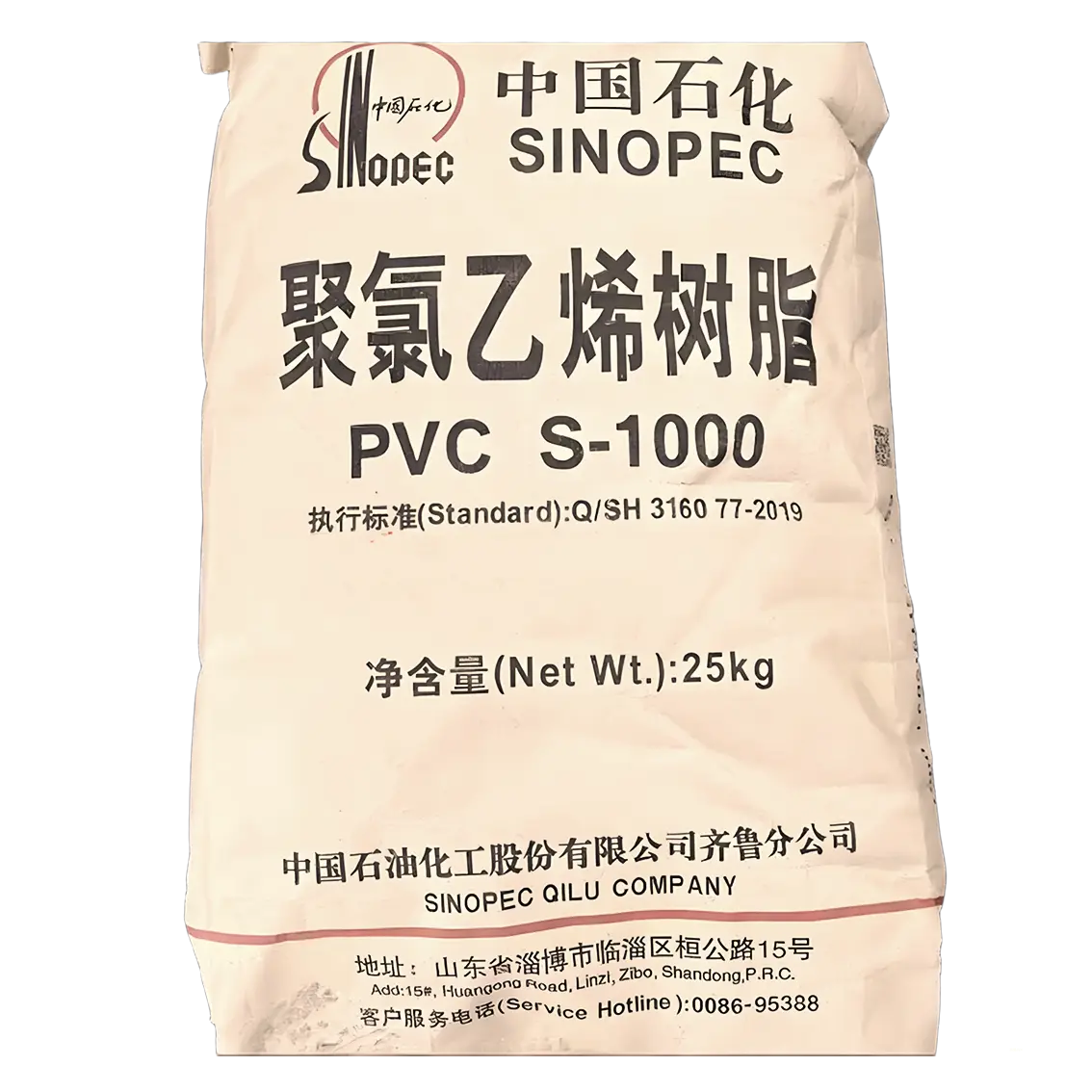

Choosing PVC S-1300 resin over lower grades like S-1000 or S-700 provides tangible competitive advantages in the marketplace. The superior performance characteristics allow you to command premium pricing while maintaining strong customer loyalty through consistently excellent product quality. This PVC resin grade is particularly valued in applications where product failure would result in significant costs or safety concerns.

Bastone's flexible MOQ policy for PVC S-1300 resin means you can manage inventory more efficiently without compromising on material quality. Our dedicated support team provides technical assistance to optimize your formulations and processing parameters, helping you maximize the performance benefits of this premium PVC resin in your specific applications.