Factory and Activities

Why Choose Bastone PVC Paste Resin?

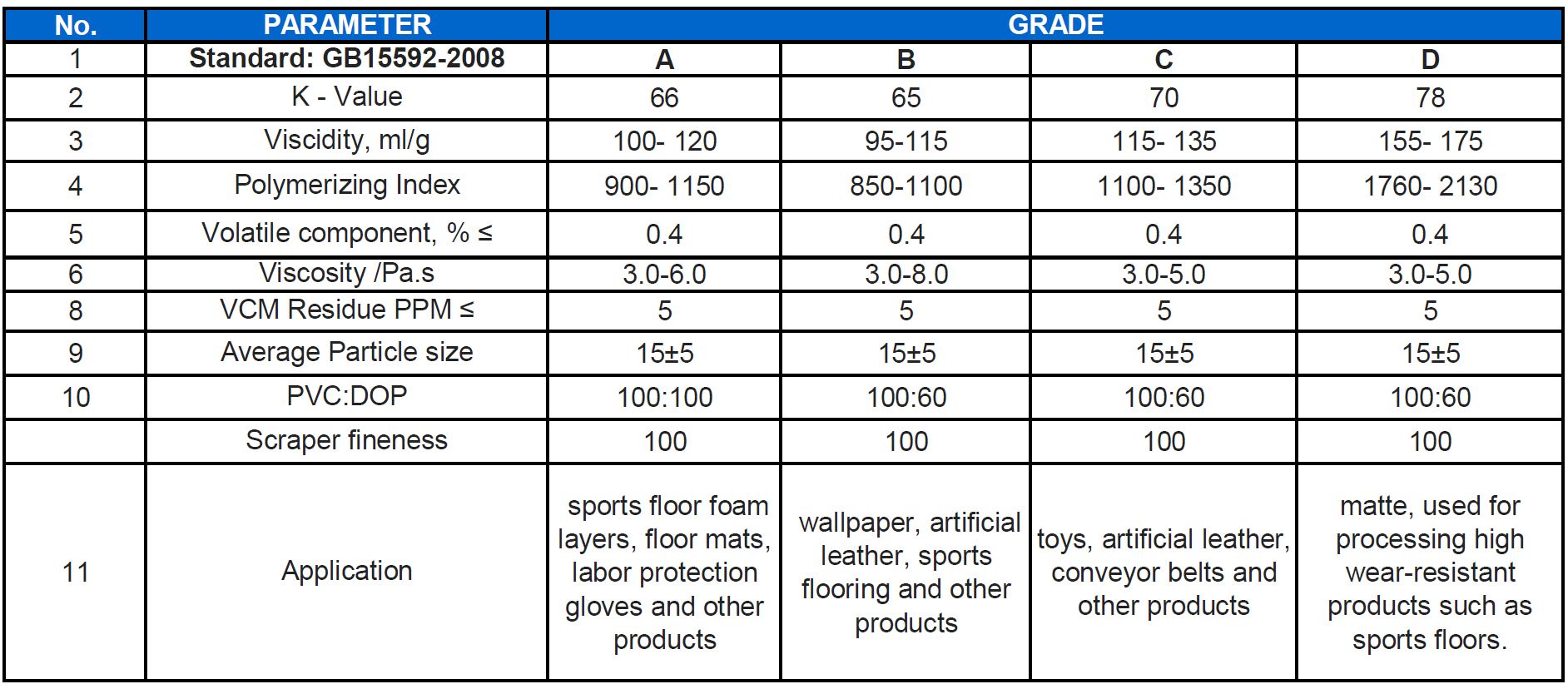

Processing Performance

Our PVC Paste Resin offers exceptional melt flow characteristics and thermal stability during processing. The resin maintains consistent viscosity throughout extrusion and molding cycles, reducing equipment downtime and material waste.

With optimal fusion temperatures and minimal degradation risk, manufacturers can achieve higher production speeds and lower energy consumption. The resin's uniform particle size distribution ensures smooth feeding and prevents blockages in processing equipment.

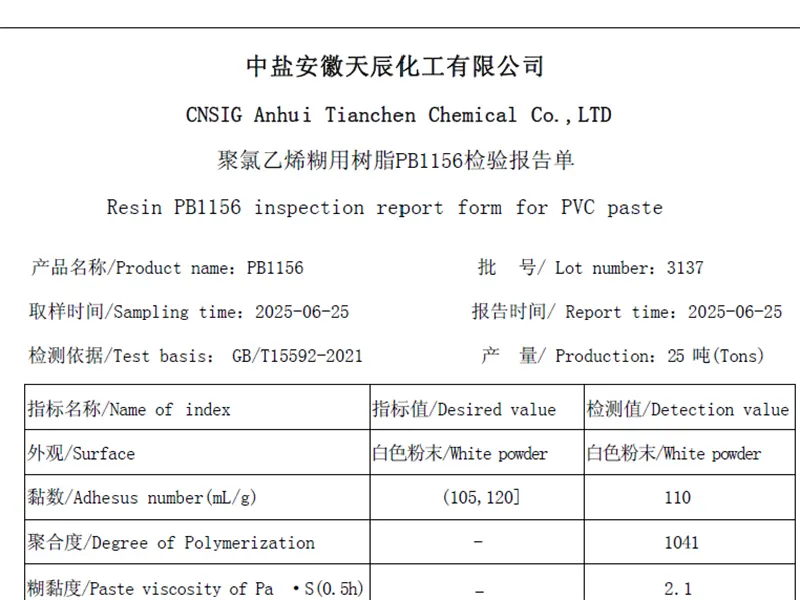

Quality Consistency You Can Trust

Every batch of our PVC Paste Resin resin undergoes comprehensive testing for particle count, moisture content, bulk density, and residual monomers. We provide detailed certificates of analysis with each shipment, documenting all critical specifications.

Our stringent screening process ensures minimal oversized particles and foreign matter, preventing defects in your final products. Consistent whiteness levels across batches mean predictable coloring results and reduced colorant usage.

Cost Efficiency for Your Bottom Line

Our PVC Paste Resin high plasticizer absorption capacity (17-19g per 100g resin) means you can achieve desired flexibility with less plasticizer, directly reducing formulation costs. The low volatile content minimizes material loss during processing and reduces the need for reprocessing scrap material.

Superior electrical conductivity values ensure efficient compound mixing, cutting blending time and energy costs. Choose the grade that matches your needs—premium for demanding applications or qualified grade for cost-sensitive projects.

Safe for Food Contact Applications

Our food-grade resin meets international safety standards with residual vinyl chloride monomer content below 5 µg/g and 1,1-dichloroethane levels under 150 mg/kg. This makes it suitable for food packaging films, drinking water pipes, medical tubing, and pharmaceutical packaging.

Complete traceability documentation and regulatory compliance certificates are available to support your product certifications and customer audits.